Sale

Sale

Make your mark with the LaserPecker LP5 - the most capable, lightest, and most compact engraver in its class. Unlock a world of creative possibilit...

View full detailsHave you ever wanted to make beautiful stone plaques or custom granite gifts that last a lifetime? A laser stone engraver can carve detailed names, images, or patterns onto rocks, marble, or granite with ease. Whether you’re making memorial stones or personalized home décor, a stone engraving laser gives you clean, lasting results without the mess of traditional carving.

With a stone engraving machine for sale, you can turn ordinary stones into unique keepsakes or business signage. A laser engraver for granite works fast and creates fine details, perfect for professional and home projects. From small pebbles to large slabs, a stone laser cutter helps you bring your creative ideas to life with precision.

Sale

Sale

Make your mark with the LaserPecker LP5 - the most capable, lightest, and most compact engraver in its class. Unlock a world of creative possibilit...

View full details Sold out

Sold out

Elevate your crafting and engraving projects with the xTool P2 55W Desktop CO2 Laser Cutter and Engraver. Meet your new business partner, the xTool...

View full details Sold out

Sold out

Meet the xTool F1 Ultra 20W Fiber & Diode Dual Laser Engraver, the world's first and best 20W dual laser system. This groundbreaking machine co...

View full details Sale

Sale

Meet the most versatile laser engraver on the market - the Gweike G7 UV Laser Engraver. 100x faster, 10x finer detail and 30x smaller spot sizes th...

View full details Sale

Sale

Unlock the Future of Precision Marking with the Gweike G6 MOPA Fiber Laser. Introducing the Gweike G6 MOPA Fiber Laser, the ultimate solution for h...

View full details Save $500.00

Save $500.00

Elevate your engraving game with the Gweike G2 Pro 30W, the cutting-edge fiber laser engraver that redefines precision and power. Experience the fu...

View full details Sale

Sale

Unleash a powerhouse of laser precision in your workspace with the Gweike Cloud 50W CO2 Laser Cutter & Engraver. Introducing the Gweike Cloud 5...

View full details Sale

Sale

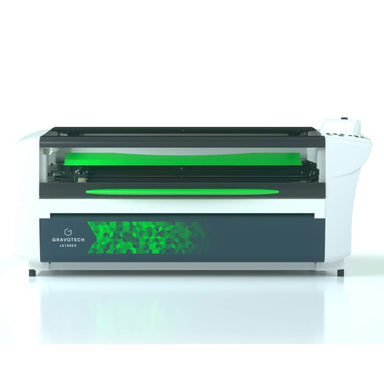

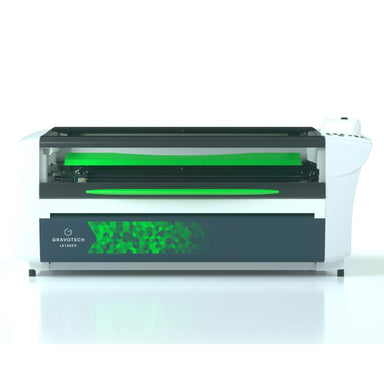

Elevate Your Engraving Capabilities with the Gravotech LS100EX Laser Engraving Machine With its large marking area, choice of CO2 or Fiber laser s...

View full details Sale

Sale

Elevate Your Engraving Capabilities with the Gravotech LS100EX Laser Engraving Machine With its large marking area, choice of CO2 or Fiber laser s...

View full details Sold out

Sold out

Elevate Your Creations with the FLUX Beambox 40W CO2 Laser Cutter. The FLUX Beambox 40W CO2 Laser Cutter & Engraver is a compact yet powerful ...

View full details Sale

Sale

Unleash industrial precision with the FSL PS48 Pro-Series Laser - the ultimate solution for heavy-duty engraving needs Experience industrial-grade ...

View full details Sale

Sale

Unleash industrial precision with the FSL PS36 Pro-Series Laser - the ultimate solution for heavy-duty engraving needs Experience industrial-grade ...

View full details Save $-8,995.00

Save $-8,995.00

Unleash industrial precision with the FSL PS24 Pro-Series Laser - the ultimate solution for heavy-duty engraving needs Experience industrial-grade ...

View full details Sale

Sale

Unleash industrial precision with the FSL PS20 Pro-Series Laser - the ultimate solution for heavy-duty engraving needs Experience industrial-grade ...

View full details Sale

Sale

Deploy the speed and precision of an UV laser source with the FSL Muse UV Galvo Laser 100x faster, 10x finer detail and 30x smaller spot sizes tha...

View full details Sale

Sale

Unleash your creativity with the power of the FSL Muse Titan Desktop CO2 Laser Cutter and Engraver - the largest desktop laser on the market! An in...

View full details Sale

Sale

Experience unparalleled power and precision with the FSL Muse MOPA Fiber Galvo Laser Tired of slow, inaccurate results from your desktop laser? The...

View full details Sale

Sale

Unlock your creative power with the precision and versatility of the FSL Muse Core CO2 Laser Cutter and Engraver Looking for the perfect machine to...

View full details Sale

Sale

Bring your visions to life like never before with the FSL Muse 3D Autofocus CO2 Laser Cutter and Engraver Are you ready to bring your laser engravi...

View full details Sale

Sale

FLUX Beamo 30W Laser Cutter & Engraver: The World's Smallest Desktop CO2 Laser Engraver and Cutter. Bring your creative ideas to life with the...

View full details Sold out

Sold out

Experience the future of desktop fabrication with the FLUX BeamBox Pro 50W CO2 Laser Cutter & Engraver. Introducing the FLUX BeamBox Pro 50W C...

View full details Save $40.00

Save $40.00

Supercharge Your Workflow with the FLUX HEXA 60W CO2 Laser Cutter. Introducing the FLUX Hexa 60W CO2 Laser Cutter & Engraver – a cutting-edge ...

View full details Save $0.00

Save $0.00

Unleash Your Creativity with the Powerful Creality Falcon2 Pro 60W Laser Engraver. Experience the power of next-generation laser technology with t...

View full details Save $0.00

Save $0.00

Unlock Your Creative Potential with the Creality Falcon2 Pro 40W Laser Engraver & Cutter. Introducing the Creality Falcon2 Pro, a state-of-the...

View full detailsYes, a laser engraver for stones can create beautiful designs, text, and images on surfaces like granite, marble, and river rocks. The laser heats the surface, causing the stone to change color or texture, resulting in a permanent mark.

A CO2 laser is often the best choice for laser engraving stone machines. It works well on granite, marble, and other natural stones, creating high-contrast markings. Fiber lasers can also engrave stone but are more suited to metals.

For laser engraving rocks or granite, a CO2 laser with at least 50 to 100 watts is recommended. Higher wattage machines provide faster engraving and deeper marks on harder stone surfaces.

Shipping Insurance ($89)