Sale

Sale

Bring Your Ideas to Life with the MY YARD FORMART 2 Vacuum Former. The MY YARD FORMART 2 Vacuum Former is your ultimate all-in-one solution for pr...

View full detailsAre you looking for a reliable way to create precise molds for your projects? A vacuum mold machine or vacuum form machine could be the solution you need. These machines are designed to create detailed plastic parts quickly and cost-effectively.

Whether you're creating prototypes or manufacturing small batches, vacuum forming machines can help streamline your process.

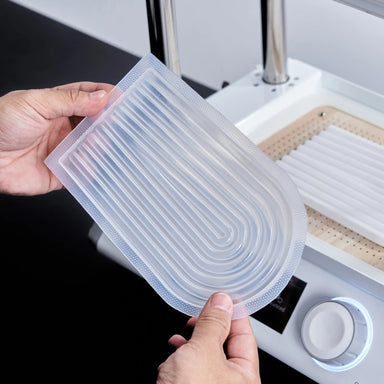

Vacuum forming machines, including vacuum thermoforming machines, are used across many industries to produce parts with excellent clarity and durability. They work by heating a plastic sheet, then using a vacuum to pull it over a mold.

Looking to speed up your production while maintaining high quality? Explore our range of vacuum former machines and discover how they can transform your manufacturing process.

Sale

Sale

Bring Your Ideas to Life with the MY YARD FORMART 2 Vacuum Former. The MY YARD FORMART 2 Vacuum Former is your ultimate all-in-one solution for pr...

View full details Sale

Sale

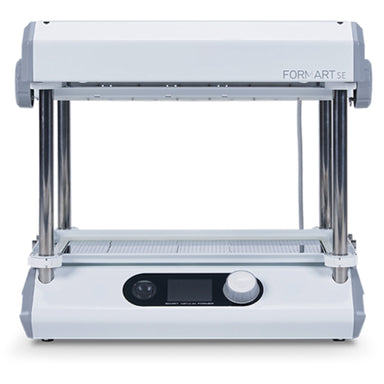

Unleash Your Creativity with the Powerhouse MY YARD FORMART SE Vacuum Former. The MY YARD FORMART SE Vacuum Former is a powerful, user-friendly so...

View full details Save $410.00

Save $410.00

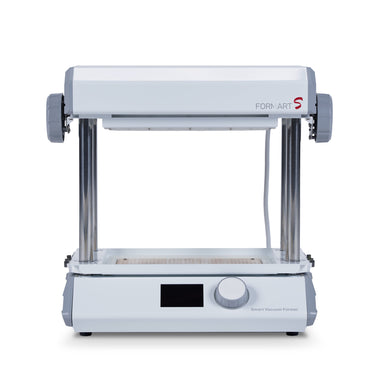

Create Professional Molds Anywhere with the MY YARD FORMART S Vacuum Former. The MY YARD FORMART S Vacuum Former is your gateway to precision mold...

View full details Sale

Sale

Transparent PET Vacuum Forming Sheet Material The PET (Polyethylene Terephthalate) was made from 80% recycled PET bottles, it has high transparency...

View full details Sale

Sale

White HIPS Vacuum Forming Sheets High impact polystyrene (HIPS) sheets have excellent forming details and dimensional stability, and are easy to co...

View full details Sale

Sale

Nature White LDPE Vacuum Forming Sheet Material Low density polyethylene (LDPE) is a light-weight, flexible and strong material, making it ide...

View full details Save $-49.00

Save $-49.00

TPU sheets, 12 x 8 inch - 0.04 inch thickness - 15 sheets Non-toxic, odorless, naturally decomposable TPU (thermoplastic polyurethanes) sheet ...

View full detailsThe main advantages of vacuum forming include cost-effectiveness, speed, and the ability to produce high-quality, detailed parts in a variety of sizes. It's ideal for creating prototypes or low-volume production runs.

However, it does have some disadvantages, such as limited material thickness and the inability to form complex internal features or undercuts without additional tooling. It’s also not as suitable for very high-volume production compared to injection molding.

The cost of a vacuum mold can vary greatly depending on the size, complexity, and material of the mold. Simple molds can range from a few hundred dollars, while more intricate designs or larger molds may cost thousands. It's essential to consider your specific needs and budget before purchasing a vacuum mold machine, as the cost of the mold is an investment that can pay off with better production efficiency and quality.

Vacuum molding works by heating a plastic sheet until it becomes soft and pliable. This heated sheet is then placed over a mold, and a vacuum is applied to pull the plastic tightly around the mold’s surface. The vacuum draws the plastic down to conform to the mold's shape, creating a precise and durable plastic part once it cools and hardens. This process is commonly used in industries like packaging, automotive, and consumer products.

Yes, vacuum forming is highly accurate, especially when using high-quality molds and machines. The process can achieve detailed shapes and fine features, but the accuracy depends on factors like mold design, material choice, and machine settings. For more intricate designs, precise molds and a well-calibrated vacuum forming machine can deliver excellent results with minimal distortion.

Shipping Insurance ($89)