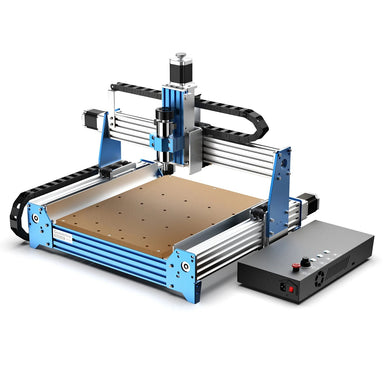

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full detailsLooking for the right desktop CNC router to bring your ideas to life? Whether you’re cutting complex shapes in wood or engraving acrylic, the right machine can make the difference between frustration and flow. What if you could get industrial-level precision right from your shop bench?

Our CNC router collection gives you machines built for versatility, speed, and stability. With features like tight accuracy, easy assembly, and support for both soft and harder materials, these routers let you focus on creating—not fixing. Explore routers that are truly ready for your projects.

Sale

Sale

Atomstack C4 Pro CNC Router: Compact Power, Big Potential! Cut, carve, and engrave across multiple materials with confidence—engineered for precisi...

View full details Save $-949.00

Save $-949.00

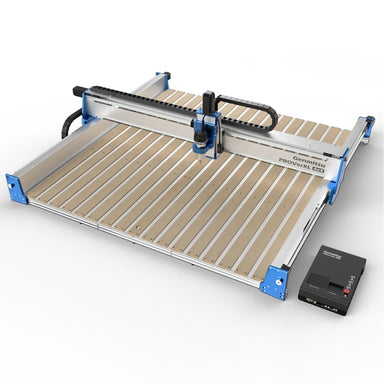

Genmitsu PROVerXL 4030 CNC Router: Expandable Power for Serious Makers! Cut wood, plastics, and metals with confidence—engineered for precision, b...

View full details Save $-1,799.00

Save $-1,799.00

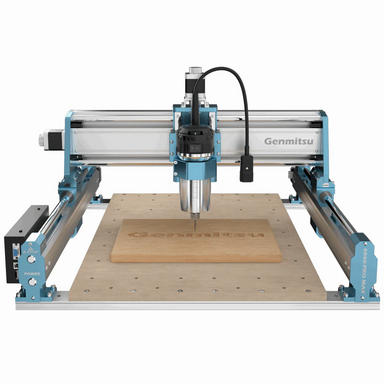

Genmitsu PROVerXL 6050 Plus CNC Router: Precision and Power for Large Projects! Cut wood, plastics, composites, and metals with ease—engineered fo...

View full details Save $-1,399.00

Save $-1,399.00

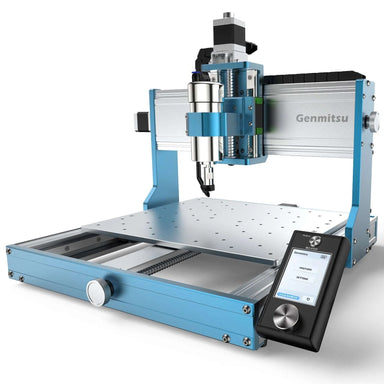

Genmitsu PROVerXL 4030 V2 Desktop CNC Router: Scalable Precision for Bigger Ideas! Cut wood, plastics, and metals with ease—engineered for strengt...

View full details Save $500.00

Save $500.00

Genmitsu PROVerXL 4x4 CNC Router: Full-Scale Precision for Ambitious Projects! Cut wood, plastics, and metals with industrial-grade power—engineer...

View full details Save $-2,999.00

Save $-2,999.00

Genmitsu PROVerXL 2X2 CNC Router: Industrial Power on Your Workbench! Cut wood, plastics, and metals with unmatched confidence—engineered for stre...

View full details Save $50.00

Save $50.00

Genmitsu Cubiko CNC Router: Compact Precision for Modern Makers! Engrave, cut, and mill with confidence—engineered for ease of use, safety, and ve...

View full details Save $70.00

Save $70.00

Genmitsu 4040-PRO MAX CNC Router: Big Projects, Bigger Precision! Take your creations further—engineered for stability, accuracy, and power, the G...

View full details Save $-849.00

Save $-849.00

Genmitsu 3030-PROVer MAX Desktop CNC Router: Power and Precision on Your Workbench! Cut metal, wood, and more with ease—engineered for accuracy, ...

View full detailsA CNC router is a computer-controlled cutting machine that can carve, cut, and engrave designs into materials like wood, acrylic, plastics, and even soft metals. The computer reads your design file and moves the spindle automatically along the X, Y, and Z axes to shape your workpiece.

Many routers can work with wood, plywood, MDF, acrylic, plastics, foam, and non-ferrous metals like aluminum (in thinner gauges). The choice of bit, feed rate, and machine rigidity determines how well it handles each material.

Not in the traditional sense—most CNC routers use software (CAD/CAM) that generates the machine paths for you. You design what you want, export the file, and the software takes care of the code. You don’t have to write G-code by hand to get started.

Routine maintenance includes cleaning chips and dust, lubricating linear guides and screws, tightening belts and hardware, and changing bits when worn. Do this regularly to keep your machine precise and extend its lifespan.

CNC routers are better suited for softer materials (wood, plastics, aluminum) and larger work areas. CNC mills tend to be stiffer and can handle harder materials and tighter tolerances. Routers are ideal for prototyping, signage, and general fabrication work.

Shipping Insurance ($89)