Unleash Limitless Creativity with the FLUX Beambox II 55W Desktop CO2 Laser Cutter. Introducing the all-new Beambox II — a powerhouse of a desktop...

View full detailsEngraving leather with a laser lets you turn simple materials into personalized, professional-grade creations. Whether you’re making custom leather patches, engraving names on wallets, or branding hat patches, a laser engraver for leather delivers precision and consistency that hand-tooling can’t match. From small desktop models for hobbyists to advanced machines for workshops, each one is designed to give you clean, permanent markings that enhance the look and feel of your work.

With options ranging from CO₂ lasers for deep, detailed burns to compact diode systems for lighter engravings, you’ll find the perfect setup to fit your needs and budget. These engravers handle both natural and faux leather, letting you experiment with designs, logos, and text on everything from fashion accessories to artisan goods. Create with confidence, knowing your results will look sharp and stand the test of time.

Save $0.00

Save $0.00

Unleash Limitless Creativity with the FLUX Beambox II 55W Desktop CO2 Laser Cutter. Introducing the all-new Beambox II — a powerhouse of a desktop...

View full details Sale

Sale

Complete your laser engraving toolchest with the ComMarker Omni 1 UV Laser Engraver and unlock more than 1,500+ materials. Multiply the types of p...

View full details Sale

Sale

Redefine UV Engraving with the Omni X: Precision, Speed, and Safety in One Powerhouse. ComMarker Omni X Laser, this isn’t just another engraver—it...

View full details Sale

Sale

FLUX Beamo 30W Laser Cutter & Engraver: The World's Smallest Desktop CO2 Laser Engraver and Cutter. Bring your creative ideas to life with the...

View full details Sale

Sale

Unleash a powerhouse of laser precision in your workspace with the Gweike Cloud 50W CO2 Laser Cutter & Engraver. Introducing the Gweike Cloud 5...

View full details Sale

Sale

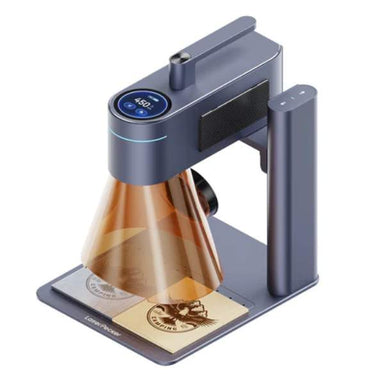

[Pre-Sale Notice]: The LaserPecker LP2 Plus is in pre-sale and the will only be shipping out to customers in the USA in early December 2025. Meet t...

View full details Sale

Sale

Supercharge your creativity with the Longer B1 Diode Laser Engraving Machine! Step into a new era of laser engraving with the Longer B1 Diode Laser...

View full details Sale

Sale

Discover precision and versatility with the ComMarker CO2 Laser Marking Machine utilizing a galvo head for ultimate speed. The ComMarker CO2 Laser ...

View full details Sale

Sale

Introducing the Atomstack Hurricane 55W CO2 Laser Cutter - Your Gateway to Limitless Creativity. The Atomstack Hurricane 55W Laser Cutter redefine...

View full details Save $160.00

Save $160.00

Elevate your small business or DIY workshop with the Monport K40 Pro - the advanced CO2 laser engraver engineered for uncompromising performance. U...

View full details Sold out

Sold out

Your Next Business Partner: The Upgraded xTool P2S 55W CO2 Laser Cutter. Transform Your crafting and engraving with the xTool P2S 55W Desktop CO2 L...

View full details Save $360.00

Save $360.00

Unleash your creativity with the powerful Gweike G1 10W laser cutter & engraver! Elevate your projects to the next level with the Gweike G1 10W...

View full details Sale

Sale

Make your mark with the LaserPecker LP5 - the most capable, lightest, and most compact engraver in its class. Unlock a world of creative possibilit...

View full details Sold out

Sold out

Meet the xTool F1 Ultra 20W Fiber & Diode Dual Laser Engraver, the world's first and best 20W dual laser system. This groundbreaking machine co...

View full details Save $100.00

Save $100.00

Meet the Laser Pecker 4 - the world's first dual laser engraver that redefines the possibilities. The LaserPecker 4 redefines the possibilities of ...

View full details Sale

Sale

Unleash your creativity with the power of the FSL Muse Titan Desktop CO2 Laser Cutter and Engraver - the largest desktop laser on the market! An in...

View full details Sale

Sale

ComMarker Omni XE UV Laser Engraver — Redefining Ultra-Fine Precision for Industrial & Creative Engraving Elevate your engraving capabilities w...

View full details Sale

Sale

The SA Laser Blade Desktop CO2 Laser — Industrial Power in a Compact Design. Meet The Blade, SA Laser’s powerful yet compact CO₂ laser system desig...

View full details Save $500.00

Save $500.00

Discover Ultra-Fine Precision and Versatility with the SCULPFUN V5 UV Laser Marking Machine. The SCULPFUN V5 UV Laser Marking Machine represents th...

View full details Save $-20,701.00

Save $-20,701.00

Meet the SA Laser XC2 Edge Series CO2 Galvo Laser — Industrial Speed Meets Unmatched Precision. The SA Laser XC2 Edge Series CO2 Galvo Laser Engrav...

View full details Sale

Sale

Dual Power, Infinite Possibilities — Precision of RF Meets the Strength of CO2 with the SA Laser Razor 3 Duo. The Razor 3 Duo represents the pinnac...

View full details Sale

Sale

SA Laser Razor 3 Brings A Larger Bed, Greater Power, Unmatched Precision — Built for Industrial-Scale Production. The Razor 3 stands at the top of ...

View full details Sale

Sale

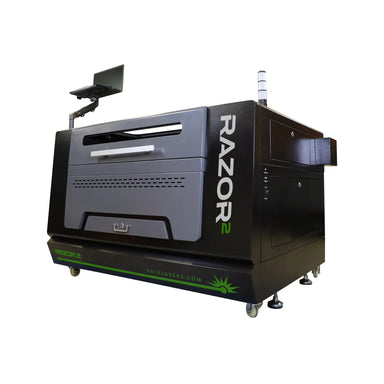

SA Laser Razor 2 Built for Production: Bigger Bed, More Power, Faster Throughput. Step up to a 24" × 40" work area, 100W CO2 tube, and servo-driven...

View full details Sale

Sale

Discover Power and Precision with the SA Laser Razor 1 Industrial CO2 Laser Engraver. Featuring brushless servo motors, HIWIN SyncMotion rails, and...

View full detailsYes — a laser can absolutely engrave leather. The focused beam vaporizes a thin layer of the material’s surface, leaving a clean, permanent mark without cutting all the way through. It works beautifully on natural, vegetable-tanned leather, producing deep contrast and detailed textures. Whether you’re personalizing wallets, belts, or leather patches, the results are precise and repeatable.

For best outcomes, use a laser engraver designed for organic materials and make sure to adjust your settings carefully to avoid excessive burn or dark edges.

A CO₂ laser is generally the best choice for engraving leather because it delivers the right wavelength for organic materials, producing smooth, dark marks without excessive charring. It’s also versatile — capable of both cutting and engraving with clean edges.

If you’re focused on detailed branding or engraving leather patches for hats or bags, a diode laser or small laser engraver for leather can also work well. The main factor is control — your ability to adjust power and speed to match the thickness and texture of the leather you’re working with.

Definitely. Engraving leather at home is a great way to personalize your craft projects or start a small business. Many compact desktop lasers are safe and efficient enough for home setups. Just make sure to have good ventilation, since burning leather releases fumes, and always work in a well-ventilated area or use a fume extractor.

Before engraving your final piece, test on a scrap of the same leather — different finishes and tanning processes can affect how the leather reacts to the laser. Once dialed in, engraving leather at home is both creative and rewarding.

For most engraving projects, you don’t need a very high-power laser. A 40W to 60W CO₂ laser provides more than enough power to engrave leather cleanly and even cut through thinner pieces if needed. For smaller machines or hobby setups, even a 10W to 20W diode laser can produce excellent engraving results when properly focused.

The key is not raw power, but fine control over your laser’s settings — power, speed, and focus. Too much power can burn or discolor the leather, while too little may result in shallow or inconsistent markings.

Engraving leather isn’t difficult once you understand the basics. The process is quite forgiving and beginner-friendly, but results depend on choosing the right material, correct focus, and proper settings. Natural vegetable-tanned leather engraves the best, while chrome-tanned or synthetic leathers can give inconsistent or overly dark burns.

The learning curve mainly involves testing your speed and power combinations to achieve clean, even tones without scorching. After a few test runs, most makers find that leather engraving becomes second nature.

Settings vary depending on your machine and leather type, but a good starting point for a CO₂ laser is low power (10–25%) and moderate speed (200–400 mm/s). This produces a clean, dark engraving without excessive burning. Always test first — lighter leather needs less power, while darker or denser leather can handle slightly higher settings.

For faux leather, use lower power and faster speeds to prevent melting or discoloration. Remember, no two leathers react the same, so testing on scraps is the best way to dial in perfect results for every project.

Shipping Insurance ($89)