Choosing between UV and IR lasers is like picking between a scalpel and a hammer—both powerful, but for different jobs! Short answer: UV wins for precision, IR for power. Curious which fits your craft best? Dive in—or explore our UV Laser Engravers Collection Page to see them in action!

Choosing between UV and IR lasers is like choosing between a scalpel and a hammer — both powerful, but meant for very different kinds of precision.

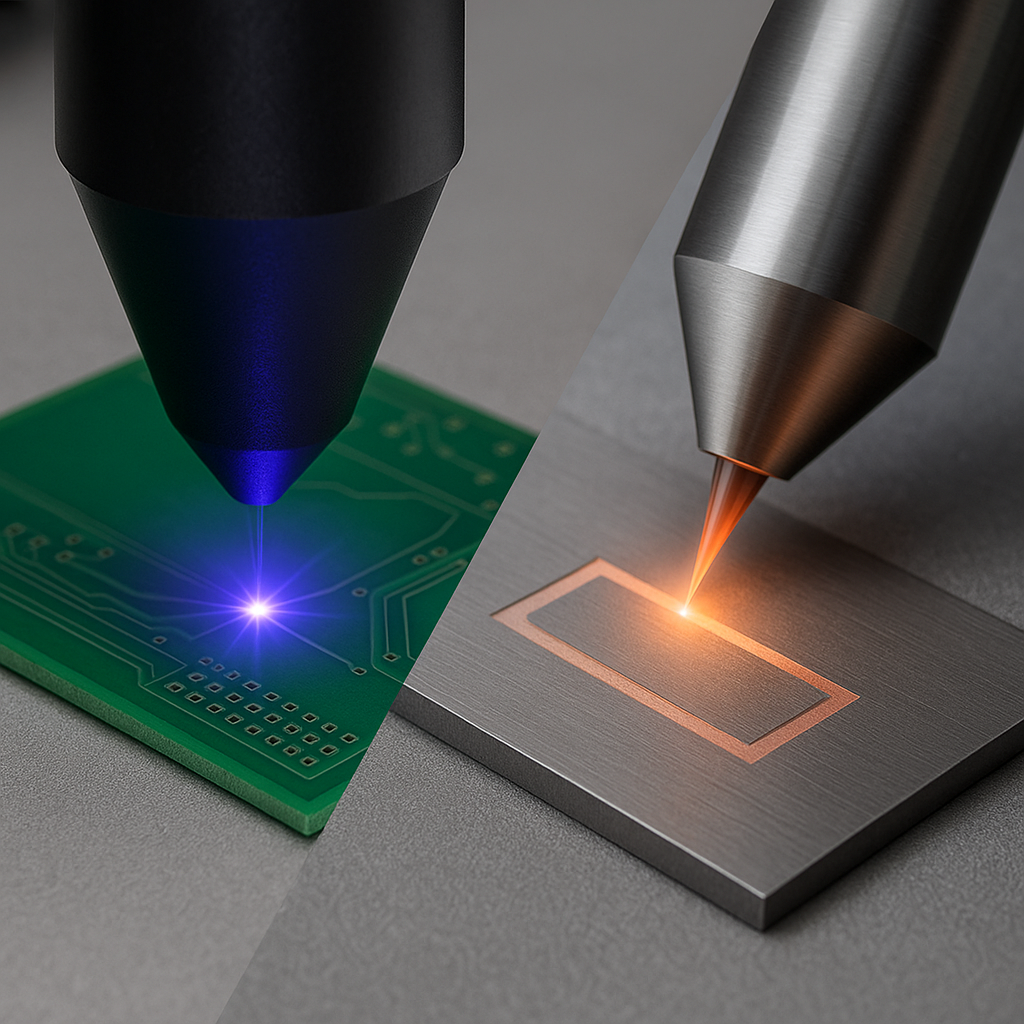

Short answer: UV lasers are unbeatable for fine, high-detail marking on delicate materials, while IR lasers dominate when you need raw power and depth, especially on metals.

If you’ve ever struggled to get the perfect balance of speed, accuracy, and material compatibility, this guide will help you decide which technology truly fits your needs.

Understanding UV and IR Laser Technology

Differences in Wavelength and Photon Energy

At the heart of the UV vs IR debate lies a single but powerful factor — wavelength.

A UV laser typically operates at 355 nanometers, part of the ultraviolet light spectrum. Because of its shorter wavelength, it carries higher photon energy. This means it interacts with the surface through photochemical reactions rather than brute heat — a process often called “cold marking.”

An IR laser, on the other hand, emits at 1064 nanometers, sitting in the infrared range. This longer wavelength delivers lower photon energy but greater penetration power, allowing it to reach deeper layers of the material.

So, in practice: UV lasers are surgical tools, perfect for precision work; IR lasers are industrial workhorses, built for depth, speed, and endurance.

How Wavelength Affects Material Interaction

When laser light hits a surface, one of three things happens: it’s reflected, absorbed, or transmitted. The wavelength determines which one dominates.

UV light, with its short wavelength, is absorbed almost instantly at the surface, which minimizes heat buildup. This is why UV lasers produce clean, contrast-rich marks even on heat-sensitive materials like plastics or glass.

IR lasers penetrate deeper, transferring energy through heat. This is fantastic for engraving metals or durable materials but can cause burns or discoloration on soft substrates.

In short: UV lasers interact chemically; IR lasers interact thermally. And that difference shapes everything from marking quality to material choice.

Material Absorption and Application Fit

Which Materials Absorb UV vs IR Best

Plastics and Polymers

If you’ve ever tried marking a plastic phone case or medical housing, you know heat can ruin it fast. UV lasers excel here. They use photochemical reactions rather than thermal ones, creating clean, high-contrast marks without melting or warping the surface.

IR lasers, while powerful, often introduce unwanted burning or discoloration. Some plastics can be treated with laser additives to improve IR absorption, but UV remains the gold standard for delicate polymers.

Transparent Materials (Glass, Quartz)

Transparent materials like glass, quartz, and crystal behave very differently under laser light. IR lasers pass straight through them, which is great for cutting but not for marking. UV lasers, however, are absorbed by the surface layer, making them capable of etching text, serial numbers, and patterns directly onto glass.

This makes UV systems popular in electronics manufacturing, where components like display glass and optical lenses need fine, permanent identification without cracking.

Coated and Bare Metals

When it comes to bare metals, IR fiber lasers are the clear winners. Their longer wavelength is absorbed efficiently by metals such as stainless steel, aluminum, titanium, and brass, producing deep, dark marks with excellent contrast.

UV lasers come into play with coated or anodized metals, where precision and surface quality matter more than depth. For example, marking a matte-black aluminum camera housing requires a light touch — exactly where UV excels.

Surface vs Deep Engraving

Surface engraving is all about finesse, not force. UV lasers excel in this area — ideal for etching intricate logos, QR codes, or calibration markings that need to stay razor-sharp.

IR lasers dominate when depth and durability are key. They’re used for engraving serial numbers on metal tools, nameplates, and engine parts where the mark must survive heat, wear, and cleaning.

Engraving Quality and Detail

Spot Size and Precision Control

The smaller the laser spot, the finer the detail — and UV lasers hold a serious advantage here. Their shorter wavelength allows for tighter focusing, producing micro-text, high-resolution logos, and even 3D microstructures.

IR lasers have a slightly larger spot size, making them better suited for bold, legible markings that need to stand out from a distance — think machine plates or industrial tags.

Minimizing Thermal Damage

Thermal control is where UV lasers truly shine. Because they rely on non-thermal photochemical reactions, they can engrave delicate surfaces like plastics or films without leaving scorch marks or residue.

IR lasers work with heat, which can create “heat-affected zones” — areas where the material melts or discolors slightly. That’s fine for metals, but risky for softer materials.

Micro-Texturing and High-Resolution Marking

For applications like medical tools, circuit boards, or microchip components, there’s no room for error. UV lasers can produce micro-scale engravings with accuracy measured in microns.

Manufacturers often use UV lasers to create invisible identifiers or anti-counterfeiting marks — so small they can only be seen under a microscope. That level of detail simply isn’t achievable with IR systems.

Performance and Cost Factors

Speed, Throughput, and Energy Usage

IR lasers win the speed race, especially when working with metals. Their deeper absorption means faster energy transfer, allowing them to complete high-volume jobs efficiently.

UV lasers, though slower, make up for it with unmatched accuracy and quality. In industries where precision outweighs quantity — such as medical devices or electronics — speed takes a back seat to perfection.

Cost of Machine and Consumables

UV laser systems are more complex to build and typically cost more upfront. However, they offer lower rework rates, minimal waste, and long-term savings through precision and reduced scrap.

IR lasers are more affordable to purchase and maintain. They’re also power-efficient, making them ideal for heavy industrial workflows where high throughput matters more than microscopic detail.

Reliability and Maintenance Considerations

Fiber IR lasers are known for their exceptional longevity, often exceeding 100,000 working hours with minimal maintenance. They’re rugged, sealed, and resistant to dust — perfect for factory environments.

UV lasers need a bit more care, as their internal optics are more sensitive. Regular cleaning and alignment ensure consistent performance. Still, they deliver excellent uptime when maintained correctly.

Both technologies are reliable — it just depends whether you value industrial endurance or precision stability more.

Choosing Between UV and IR

Application-Based Decision Guide

| Application |

Best Choice |

Why It Works |

| Plastic housings, circuit boards, medical casings |

UV Laser |

Gentle surface marking with zero melting |

| Metal tags, aerospace tools, machinery |

IR Laser (Fiber) |

Deep engraving with strong contrast |

| Glass components, crystal gifts |

UV Laser |

Marks without cracks or stress fractures |

| Automotive or aerospace parts |

IR Laser |

High-speed, permanent metal engraving |

| Branding & decorative etching |

UV Laser |

Clean, detailed designs with smooth edges |

Pros and Cons Summary

UV Lasers

✅ Delivers unmatched precision and fine detail.

✅ No thermal damage — ideal for sensitive materials.

✅ Works beautifully on plastics, glass, and coated metals.

❌ Slower marking speed and higher upfront cost.

IR Lasers

✅ Fast, powerful, and perfect for metals.

✅ Low maintenance and long lifespan.

✅ Great for industrial, high-throughput environments.

❌ Generates more heat and less suitable for fine textures.

What Industries Use Each Type Most

-

UV Lasers: Electronics, semiconductors, medical manufacturing, luxury packaging, and product branding.

-

IR Lasers: Automotive, aerospace, industrial tooling, and heavy manufacturing.

From delicate watch dials to hardened aircraft components, each laser type has its sweet spot.

Final Thought:

If you need high precision, cool marking, and flawless edges, UV is the way to go. If your priority is speed, durability, and deep engraving, IR is your trusted powerhouse.

The key is matching the tool to your task. Your best results will always come from understanding your materials, your production goals, and the laser that complements them best.

To see these technologies in action, visit our [UV Laser Engravers Collection Page] — and find the system that helps you make your mark, your way.

You May Also Like:

Leave a comment