Ever wondered why your “perfect” laser engraving looks more like toast than art? 😅 Here’s the short answer: UV lasers beat diode lasers for precision and delicate materials. But before you grab one, discover why in our full UV Laser Engravers Collection Page comparison — your projects will thank you!

If you’ve ever tried engraving a plastic phone case or glass mug only to end up with burnt edges or cracks, you’ve probably learned this the hard way — not all lasers are created equal.

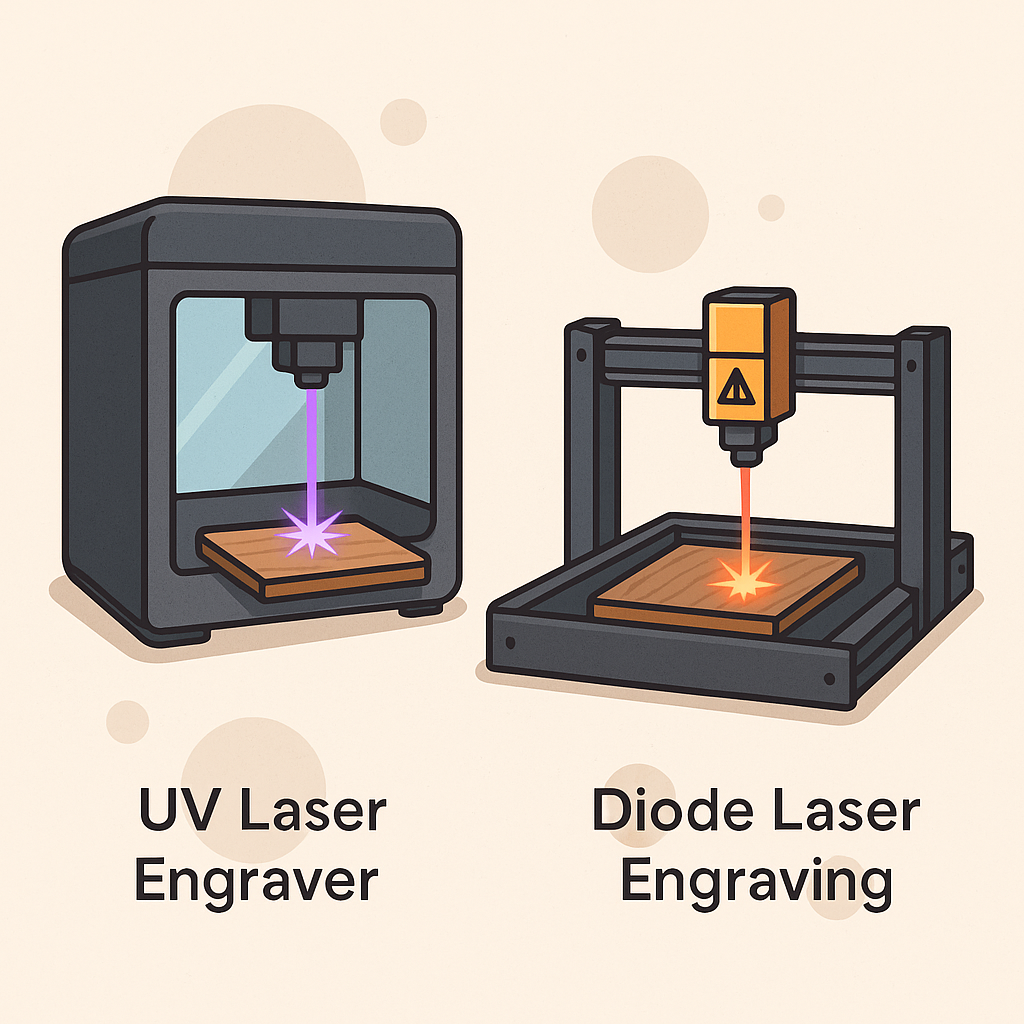

Choosing between a UV laser and a diode laser can feel a bit like picking between a race car and an off-road truck. Both are powerful. Both get the job done. But how they get there — that’s where the difference lies.

This guide breaks down the real differences between UV and diode lasers — not just specs, but how they behave in the real world. By the end, you’ll know exactly which one suits your projects, budget, and creative goals.

(Short answer: UV lasers win for precision and delicate materials, diode lasers win for affordability and versatility — but there’s more to the story.)

Introduction to UV and Diode Lasers

How Each Laser Type Works

Let’s start with the basics.

A UV laser engraver uses what’s known as cold laser technology. Instead of burning, it uses short ultraviolet wavelengths to break molecular bonds directly at the surface. Think of it as carving ice with a scalpel — crisp, clean, and almost effortless.

A diode laser, by contrast, is a heat-based system. It uses visible or infrared light (typically blue or near-infrared) to heat and vaporize the surface. That makes it fantastic for wood, leather, and coated metals — materials that respond well to controlled heat. But it’s not ideal for plastics, glass, or materials that can warp or discolor.

In simple terms: UV is surgical precision; diode is creative muscle.

Common Wavelengths and Technologies

-

UV Lasers usually operate around 355 nm — right in the ultraviolet range. That shorter wavelength means the light interacts differently with materials, causing photoablation (a fancy term for vaporizing matter without heat damage).

-

Diode Lasers, on the other hand, run between 450 nm and 1064 nm, depending on the module. These longer wavelengths penetrate deeper but bring heat along for the ride.

That’s why a UV laser can etch micro text onto a contact lens, while a diode laser is busy engraving a leather wallet with your logo. Both impressive — but very different strengths.

What Makes UV Lasers Unique

What truly sets UV lasers apart is their ability to engrave heat-sensitive materials like glass, acrylic, ABS plastic, or even silicon chips.

Because UV lasers don’t rely on heat, they don’t burn edges or leave residue. The finish is crisp and consistent — no sanding, polishing, or cleanup required. This makes them indispensable for industries like medical manufacturing, electronics, and fine jewelry, where precision is everything.

If you’re after micro-detail or engraving logos smaller than a grain of rice, a UV laser is the only real contender.

Performance and Precision

Spot Size and Resolution

Spot size determines how fine your engraving can be — and UV lasers excel here. Their beam can reach sizes as small as 10–15 microns, allowing for intricate text, sharp barcodes, or artwork with hairline precision.

Diode lasers generally produce a wider beam — anywhere from 50–100 microns. Perfectly fine for hobbyist engraving, but not ideal for projects that demand ultra-sharp detail.

If you want to mark jewelry, circuit boards, or high-end branding plates, UV wins. If you’re engraving cutting boards, signs, or decor, diode is plenty.

Material Compatibility

Metals

UV lasers can handle both coated and bare metals, including stainless steel, aluminum, and brass. They can mark serial codes or company logos with laser-sharp contrast — literally. Diode lasers, however, typically require a marking spray or coating to achieve visible results on metal. They can mark, but not truly engrave.

Plastics and Acrylics

Here’s where the UV laser truly shines. Plastics are prone to warping and melting under heat, but UV lasers sidestep that entirely. The result? Smooth, uniform marks without deformation or burn lines. Diode lasers can work with certain plastics (like painted acrylic or coated surfaces), but they struggle with transparency or heat-sensitive blends.

Glass and Ceramics

Glass and ceramics are notoriously tricky — crack too easily, absorb heat unevenly, and reflect light unpredictably. UV lasers handle these materials like pros, creating frosted, flawless finishes. Diode lasers can engrave glass in some cases (with coating or masking), but the risk of cracks and inconsistent texture is high.

Speed and Engraving Depth

Speed isn’t just about how fast the laser moves — it’s about how much power and precision it maintains while moving.

A diode laser can cut and etch soft materials at impressive speeds, making it ideal for production runs on wood or coated metal. A UV laser may move slower in some settings, but every pass is incredibly precise and clean. It also allows for deeper, more controlled engraving, perfect for product identification or fine art.

If you care about visual quality over raw pace, UV wins. If speed and cost-efficiency drive your work, diode takes the lead.

Cost, Lifespan, and Maintenance

Upfront and Long-Term Costs

The price gap between UV and diode lasers is significant. A diode laser can cost as little as $200–$1,000, perfect for beginners, small shops, or creators testing the waters.

A UV laser, however, typically starts around $3,000 and can exceed $10,000+ for industrial-grade units. But what you’re paying for is precision, repeatability, and durability. For professional or industrial use, the ROI quickly makes sense.

Many businesses offset that cost by offering specialized engraving — medical tools, high-end branding, or electronics marking — areas where UV lasers command higher margins.

Maintenance Requirements

UV lasers need a bit of pampering. They rely on precision optics that must stay clean and calibrated. They thrive in dust-free environments and benefit from regular inspection.

Diode lasers are far more forgiving. Their modules are simple, sealed, and easy to replace. A quick lens cleaning and occasional alignment check are usually all that’s needed. For anyone who hates maintenance — diode wins for simplicity.

Lifespan of UV vs Diode Lasers

A UV laser typically lasts between 10,000–20,000 hours, maintaining beam stability almost until the end. A diode laser usually averages 5,000–10,000 hours, with brightness gradually fading over time.

If you’re a casual user, diode lifespan is more than enough. For commercial work, UV longevity and consistency make it the smarter investment.

Best Use Cases for Each Type

When to Choose a UV Laser Engraver

If you need fine, permanent, professional-quality engraving, UV is your go-to. Industries like electronics, medical devices, automotive parts, and luxury goods rely on UV lasers for marking everything from circuit boards to perfume bottles.

They’re also fantastic for branding or personalization businesses that work with mixed materials — think jewelry, promotional items, or glassware.

Explore the full lineup in our UV Laser Engravers Collection Page — where precision meets practicality.

When a Diode Laser Makes More Sense

If you’re just starting out or mainly engraving wood, leather, or coated metals, a diode laser is a fantastic choice. It’s portable, affordable, and surprisingly capable for hobbyists, Etsy shop owners, or small makers.

Diode lasers are also easier to use in shared spaces or home studios — just plug in, calibrate, and start creating.

Are There Hybrid or Combo Solutions?

Yes — and they’re game changers. Some modern systems combine UV, IR, and diode lasers into one body, letting you swap wavelengths for different materials. They’re pricier but give unmatched flexibility.

If your workflow involves both delicate and rugged materials, a hybrid laser is worth every penny.

Final Thoughts and Buyer’s Guide

Who Should Choose UV Over Diode?

Choose a UV laser if precision, consistency, and versatility across materials are non-negotiable. It’s the professional’s pick — ideal for industries that require perfect detailing, long-term reliability, and zero surface damage.

Choose a diode laser if you want something practical, portable, and budget-friendly for everyday projects. It’s an excellent starting point with room to grow.

Things to Consider Before Purchasing

Before investing, ask yourself:

- What materials do you engrave most often?

- How much precision do your clients demand?

- Do you have space for proper ventilation or a clean environment?

- Are you looking for speed, accuracy, or both?

A little planning now ensures your laser fits your workflow — not the other way around.

Real-World Comparison Examples

A luxury jeweler uses a UV laser to micro-engrave hallmarks on 18k gold. A wood craftsman relies on a diode laser to personalize 200 cutting boards a day. A tech manufacturer uses UV engraving to label polymer components without melting them.

Different lasers. Different strengths. Same goal: precision craftsmanship.

Conclusion

Here’s the bottom line:

💡 UV lasers deliver unmatched precision, stability, and quality for professional applications.

🔥 Diode lasers offer affordability, versatility, and ease for creative and small business users.

You May Also Like:

Leave a comment