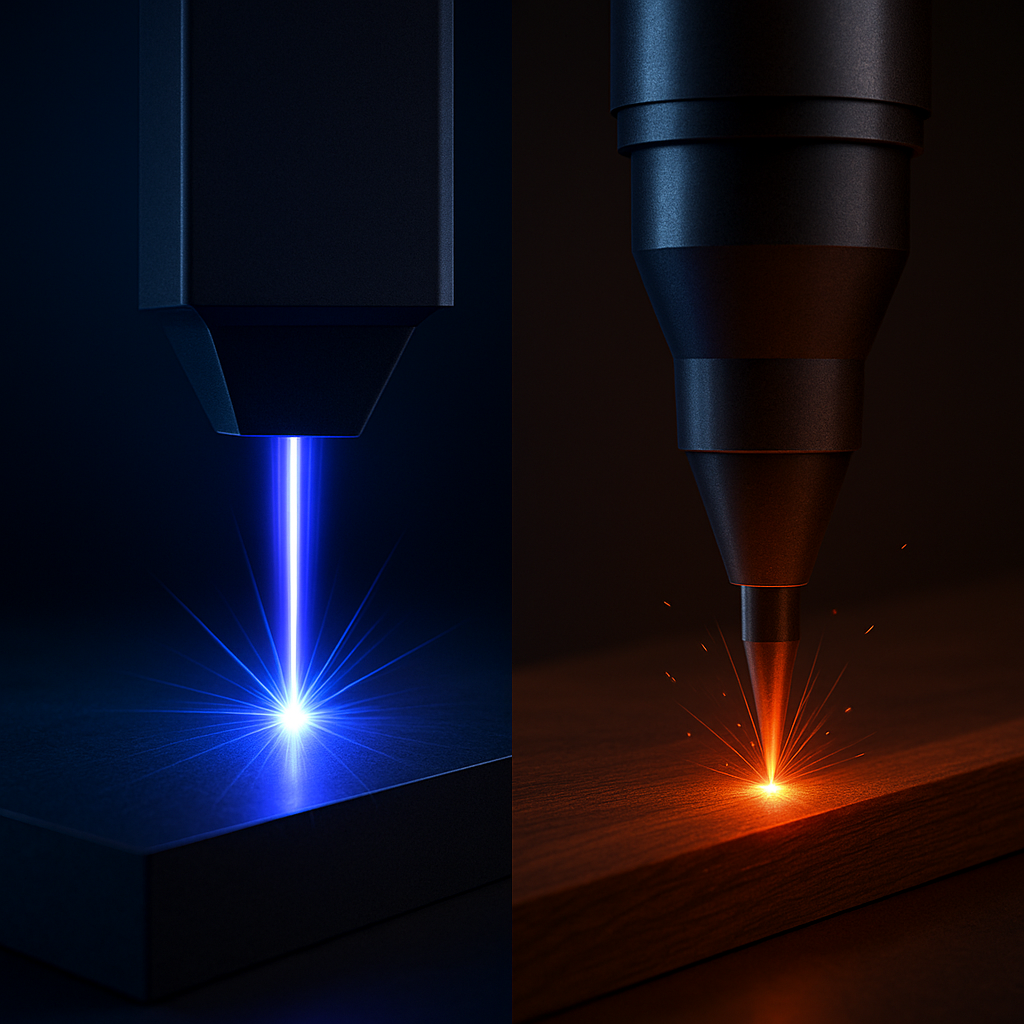

Ever wondered who wins in the battle of beams — UV Laser vs CO2 Laser? Short answer: it depends! UV lasers shine in precision, while CO2 lasers rule in power. Dive in to see which one fits your projects best — and explore our UV Laser Engravers Collection Page for inspiration!

Ever found yourself staring at two laser machines and thinking, “Okay, but which one’s actually better — UV or CO2?”

Here’s the short answer: it depends on what you’re making.

If your goal is to achieve fine, flawless detail without burning or discoloration, the UV laser is the star of the show. But if you’re cutting through thicker materials like wood or acrylic and need power over precision, the CO2 laser is your go-to.

Let’s break it all down — from how they work to which materials they love most — so you can make the right choice for your shop, lab, or creative workspace. And if you’re leaning toward precision, don’t miss our UV Laser Engravers Collection Page for a closer look at top-rated systems.

UV vs CO2 Laser – How They Work

Wavelengths and Laser Generation Methods

Think of laser light like the color spectrum — except we’re talking energy, not paint. UV lasers operate in the ultraviolet range (around 355 nanometers), which is incredibly short and energetic. They’re created by converting a standard infrared laser through a process called frequency tripling.

That shorter wavelength means UV lasers can focus tighter and interact with materials differently — the energy penetrates only the surface instead of heating the whole structure. It’s like carving with light tweezers instead of a branding iron.

CO2 lasers, on the other hand, live in the infrared zone (10.6 micrometers). Their beam comes from a gas mixture — carbon dioxide, nitrogen, and helium — excited by an electric current. The result? A long-wavelength powerhouse capable of burning, cutting, and vaporizing thicker materials.

It’s the difference between surgical precision and raw industrial strength.

Types of Energy Absorption

The way each beam interacts with matter is what makes them so unique. UV lasers are easily absorbed by most materials — plastics, ceramics, metals, even glass — because their high photon energy breaks molecular bonds directly. That’s why they can engrave delicate smartphone components or medical instruments without leaving heat marks.

CO2 lasers, by contrast, work best when their infrared light is absorbed by organic materials — things rich in carbon, like wood, leather, and paper. They melt or vaporize these materials cleanly, producing smooth, dark edges ideal for engraving or cutting signage and décor.

Hot vs Cold Marking

This is where the two lasers show their personalities.

UV lasers perform what’s called cold marking — their light energy causes a photochemical reaction instead of a thermal one. That means almost no heat, no burning, and no damage to nearby material. If you’re engraving a medical syringe, a phone circuit board, or a jewelry tag, that’s exactly what you want.

CO2 lasers, in contrast, use thermal marking — they heat up the surface until it vaporizes. It’s fast and powerful but introduces a heat-affected zone (HAZ). For most organic materials, this is fine, but for sensitive or reflective surfaces, it can mean warping or discoloration.

Material Compatibility

Which Materials Work Best with Each Type

Organic vs Inorganic Substrates

If materials were food, UV lasers would be your precision sous chef — ideal for delicate dishes. They handle inorganic materials like glass, ceramics, and metals with microscopic control. The result? Crystal-clear etching and razor-thin lines.

CO2 lasers are more like a barbecue grill — designed for organic materials like wood, leather, or textiles. They burn cleanly and leave beautiful dark contrast, perfect for cutting signage, home décor, or custom packaging.

Coated vs Bare Metals

This is where UV lasers really earn their keep. They can mark coated, anodized, or painted metals without damaging the layer underneath. That’s why industries like electronics, aerospace, and medical manufacturing rely on them.

For instance, when marking serial codes on a titanium surgical tool, even a few degrees of excess heat can cause structural changes. A UV laser avoids that entirely.

CO2 lasers, however, struggle with bare or polished metals since infrared light tends to reflect off them. You can use a metal marking spray or compound to help absorption, but it’s an extra step that adds time and cost.

Transparent Materials

Here’s a fun one: ever tried engraving clear acrylic with a CO2 laser and nothing happened? That’s because CO2 wavelengths pass straight through transparent materials. UV lasers, on the other hand, can engrave and etch clear surfaces like glass or crystal with pinpoint precision — no cracking, no frosting. That makes them the go-to for glass trophies, mirrors, and luxury packaging.

Thermal Impact and Charring

You can always spot a CO2 laser job by its slightly burned or browned edges — a badge of honor for makers who love contrast. But that same heat can cause charring, especially on light-colored materials.

UV lasers eliminate this issue. They operate so cleanly that there’s no carbonization, no smoke marks, and no post-processing required. That’s why they’re often used for high-end branding and medical-grade labeling where surface integrity matters.

Resolution, Accuracy, and Edge Quality

Spot Size and Precision

If detail is what you’re after, UV lasers take the crown. Their tiny spot size (10–20 microns) allows them to mark micro-text, intricate barcodes, and detailed logos you could fit on a grain of rice.

CO2 lasers, while less precise, are unbeatable when size and speed matter — cutting through ¼-inch wood or acrylic sheets with ease.

Heat-Affected Zones and Microcracks

When using a CO2 laser on brittle materials like glass, microcracks can form from sudden temperature changes. UV lasers, with their cold processing, bypass that issue entirely. The result? Smooth, damage-free marks that look factory-perfect even under a microscope.

Depth Control and Repeatability

UV lasers excel at shallow, consistent markings — the kind needed for serial numbers, microchips, or medical labels. CO2 lasers are built for depth — ideal for engraving into wood, leather, or rubber stamps.

If you’re running production batches, UV’s stability ensures identical results every time, while CO2’s power lets you scale quickly on thicker materials.

Operational Considerations

Throughput and Processing Speed

When speed is everything — say, cutting dozens of acrylic panels — CO2 lasers are your best bet. Their high wattage and fast scanning speeds make quick work of large jobs.

UV lasers move slower, but what they lack in pace they make up for in perfection. If your goal is consistent, flawless micro-detailing, you’ll never regret choosing UV.

Power Requirements and Cooling

CO2 lasers tend to run hotter and often rely on water-cooling systems to stay efficient.

UV lasers, being diode-pumped and more compact, are air-cooled, consuming less power and needing less upkeep. That efficiency translates into lower long-term operating costs and fewer interruptions on the production floor.

Cost of Operation and Maintenance

A CO2 laser is generally cheaper to buy, maintain, and replace parts for. It’s a workhorse — dependable, cost-effective, and easy to operate. A UV laser, though more expensive upfront, pays for itself in precision, low waste, and high-quality output.

For example, an electronics manufacturer using UV can avoid rejects due to heat damage, saving time and materials — a long-term ROI that easily justifies the initial price.

Choosing the Right Laser for Your Needs

Recommended Use Cases for UV Lasers

Pick a UV laser if your projects involve:

- Marking delicate plastics, ceramics, or coated metals

- Creating fine, permanent logos or serial codes

- Etching glass or transparent materials

- Working in industries where precision and cleanliness matter — like medical, aerospace, or electronics

If you need to mark something that looks beautiful under a microscope — UV is the one.

Where CO2 Lasers Still Shine

Go for a CO2 laser when you need:

- Fast cutting on organic materials

- Deep engraving on wood, leather, or acrylic

- Affordable, versatile production power

- Custom signage, decorative pieces, or packaging

It’s the classic “maker’s laser” — powerful, simple, and capable of handling a wide range of creative and commercial tasks.

Should You Consider Both?

Many modern workshops use both technologies together. A UV laser handles the delicate work — intricate marks, logos, and micro details — while a CO2 laser powers through bulk cutting and large engravings.

This combination gives you the best of both worlds: speed and strength from CO2, precision and finesse from UV. It’s like having both a paintbrush and a power saw — each one perfect for a different kind of masterpiece.

Final Thoughts

So, which laser is better? That depends on your goals.

If your work demands flawless precision, no heat damage, and tight control — go with UV. If you value cutting speed, affordability, and versatility — CO2 is your reliable partner.

At the end of the day, both technologies push the boundaries of what’s possible with light. And when you’re ready to take your projects to the next level, explore our UV Laser Engravers Collection Page — where precision meets creativity, and every mark tells a story.

You May Also Like:

Leave a comment