Sale

Sale

Redefine UV Engraving with the Omni X: Precision, Speed, and Safety in One Powerhouse. ComMarker Omni X Laser, this isn’t just another engraver—it...

View full detailsLooking for a way to mark delicate materials without damage? A UV laser marking machine offers ultra-fine precision, making it perfect for plastics, glass, and metals. Whether you're engraving serial numbers, barcodes, or intricate designs, UV laser etching delivers crisp, high-contrast results without generating heat damage.

From industrial labeling to custom artistry, a UV laser cutter ensures smooth, detailed cuts on sensitive surfaces. Unlike traditional methods, a UV laser machine provides fast, contact-free engraving with long-lasting durability. Ready to upgrade your workflow? Explore our top-rated models below!

Sale

Sale

Redefine UV Engraving with the Omni X: Precision, Speed, and Safety in One Powerhouse. ComMarker Omni X Laser, this isn’t just another engraver—it...

View full details Sale

Sale

Complete your laser engraving toolchest with the ComMarker Omni 1 UV Laser Engraver and unlock more than 1,500+ materials. Multiply the types of p...

View full details Sale

Sale

ComMarker Omni XE UV Laser Engraver — Redefining Ultra-Fine Precision for Industrial & Creative Engraving Elevate your engraving capabilities w...

View full details Sale

Sale

Delicate Precision Meets Powerful Performance: Introducing the Haotian UV Galvo Laser Engraver. The Haotian UV Galvo Laser Engraver is engineered f...

View full details Save $500.00

Save $500.00

Discover Ultra-Fine Precision and Versatility with the SCULPFUN V5 UV Laser Marking Machine. The SCULPFUN V5 UV Laser Marking Machine represents th...

View full details Sale

Sale

Meet the most versatile laser engraver on the market - the Gweike G7 UV Laser Engraver. 100x faster, 10x finer detail and 30x smaller spot sizes th...

View full details Sale

Sale

Achieve Unparalleled Precision and Versatility with the Haotian 3D Feeltek UV Galvo Laser Engraver: Engrave curved surfaces with ease. Unlock your...

View full details Sale

Sale

Deploy the speed and precision of an UV laser source with the FSL Muse UV Galvo Laser 100x faster, 10x finer detail and 30x smaller spot sizes tha...

View full details Sale

Sale

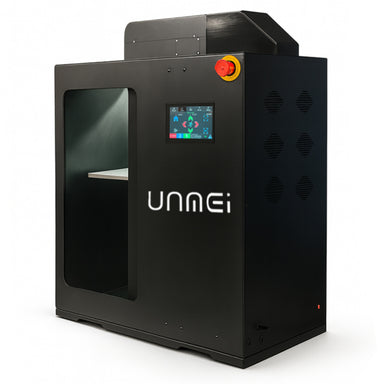

Next-Generation 3D UV Marking — Precision Meets Portability with the FSL Unmei Compact UV Laser System. A Compact 3D UV Laser System Built for Prec...

View full detailsThe biggest difference lies in wavelength and material compatibility. Fiber lasers operate around 1064 nm, which is ideal for marking and engraving metals like stainless steel, aluminum, and brass. UV lasers use a much shorter wavelength (355 nm), which allows them to mark delicate materials such as plastics, glass, silicone, and even thin films — without burning or melting them.

In essence, fiber lasers excel at deep and permanent engraving on metals, while UV lasers specialize in cold marking — a low-heat process that delivers ultra-fine detail on sensitive surfaces. That’s why industries like medical device manufacturing, electronics, and packaging often prefer UV lasers for precision and surface-safe results.

A UV laser engraver creates precise, high-contrast marks on a wide range of materials, including plastic, glass, ceramics, and metals. It’s commonly used for barcodes, QR codes, logos, and serial numbers in industries like electronics, medical devices, and packaging. Since UV lasers work with low heat, they prevent damage to sensitive materials, making them ideal for intricate engraving applications.

A UV laser marking machine is used to create permanent, high-precision markings on non-metallic and metal surfaces without physical contact. It's widely used in industries where accuracy and durability are essential, such as medical equipment, electronics, and security labeling. The cold laser process ensures clean, detailed marks without burning or distorting the material.

A UV laser machine can engrave and mark materials such as plastics, glass, ceramics, metals, leather, and coated surfaces. Its low-heat process ensures crisp, clear markings without warping or damaging the material.

A high-quality UV laser source typically lasts 10,000 to 20,000 hours, depending on power level, cooling efficiency, and maintenance. Systems using JPT or Inno series modules tend to maintain consistent output over many years with minimal degradation.

Regular cleaning of optics, proper ventilation, and avoiding overdriving the power supply can greatly extend lifespan. In practical terms, that’s several years of use for most businesses — making UV lasers a long-term, low-maintenance solution for precision marking and engraving.

The main difference between a 5W and 10W UV laser engraver is power and throughput. A 10W UV laser can mark or engrave materials faster, with deeper penetration and better contrast, especially on metals and industrial plastics. This makes it ideal for production environments or applications that demand higher efficiency, like barcode marking or deep engraving on coated components.

A 5W UV laser, on the other hand, is often more affordable and compact. It’s perfectly suited for fine detail work — like jewelry, micro-electronics, or small plastics — where you don’t need to cut or engrave deeply. In short, choose 10W if you need speed and productivity, and 5W if precision and cost-efficiency matter most.

In most cases, low-power UV lasers (like 3W–10W models) do not require a separate water chiller. These compact systems are air-cooled and designed for efficient heat dissipation, making them suitable for light to moderate engraving or marking tasks without external cooling. Built-in fans or heat sinks are usually sufficient to maintain optimal operating temperatures.

However, higher-power UV lasers (≥15W) or industrial-grade units designed for continuous production often benefit from — or require — a water chiller. Because UV lasers operate with delicate optics and short wavelengths, excess heat can degrade beam quality and shorten the laser module’s lifespan. A dedicated chiller keeps the temperature stable, protects the optics, and ensures consistent engraving precision during long runs.

If your machine will be running for hours each day or in a warm environment, a compact water chiller is a smart investment to maintain performance, stability, and longevity.

Yes, a UV laser can engrave wood — but it’s not the most efficient choice. The 355 nm wavelength is designed for marking sensitive materials, not cutting or burning organic surfaces like a CO₂ or diode laser would. When used on wood, a UV laser can produce very fine, high-contrast markings with minimal charring, which is useful for branding or logos that require micro-precision.

However, if your goal is cutting or deep engraving, a CO₂ laser is a better tool. UV lasers are meant for surface marking and detail work rather than removing large amounts of material.

No, standard UV lasers — even higher-powered ones — are not designed for cutting metal. Their beam excels at marking, not material removal. The short wavelength allows precise surface etching, serial number engraving, or barcode marking on metals, but it doesn’t have the power density to slice through them.

If your application involves cutting aluminum or stainless steel, a fiber laser (50W or higher) or a CO₂ laser with assist gas would be required. UV lasers are best viewed as marking tools for fine, permanent identification rather than metal fabrication.

UV lasers can mark and lightly engrave acrylic with exceptional detail, producing smooth, frosted results without yellowing or edge burning. Because UV operates with minimal heat, it’s ideal for precision surface marking on clear or colored acrylic where clarity is important — such as control panels, nameplates, or decorative signage.

However, UV lasers are not powerful enough to cut through thick acrylic sheets. For cutting 3 mm or thicker acrylic, a CO₂ laser is recommended, as it melts and vaporizes the material cleanly. UV lasers are better suited for engraving fine patterns, text, or logos on acrylic’s surface.

Shipping Insurance ($89)