Sale

Sale

Unleash a powerhouse of laser precision in your workspace with the Gweike Cloud 50W CO2 Laser Cutter & Engraver. Introducing the Gweike Cloud 5...

View full detailsDo you love working with wood and want to add intricate details to your projects? A laser engraver for wood makes it easy to personalize crafts, gifts, and business products with precision and speed. Whether you're using a wood laser cutting machine for crafts or a wood laser engraver and cutter for professional work, these machines give you endless creative possibilities.

From delicate etching to deep engraving, a wood laser engraver machine can handle various materials and thicknesses. Perfect for hobbyists and businesses alike, a wood engraving machine ensures clean, precise cuts without the mess of traditional tools. Bring your ideas to life with the power of laser technology!

Sale

Sale

Unleash a powerhouse of laser precision in your workspace with the Gweike Cloud 50W CO2 Laser Cutter & Engraver. Introducing the Gweike Cloud 5...

View full details Sold out

Sold out

Elevate Your Creations with the FLUX Beambox 40W CO2 Laser Cutter. The FLUX Beambox 40W CO2 Laser Cutter & Engraver is a compact yet powerful ...

View full details Sold out

Sold out

Elevate your crafting and engraving projects with the xTool P2 55W Desktop CO2 Laser Cutter and Engraver. Meet your new business partner, the xTool...

View full details Sale

Sale

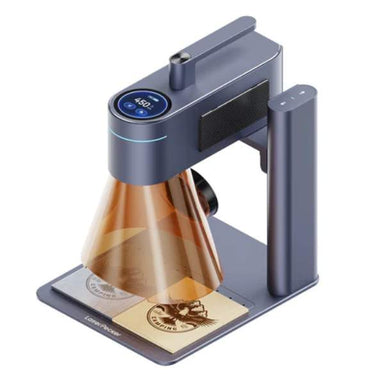

Make your mark with the LaserPecker LP5 - the most capable, lightest, and most compact engraver in its class. Unlock a world of creative possibilit...

View full details Sold out

Sold out

Unleash Your Creative Genius with the Unparalleled Power of the xTool S1 Laser Engraver and Cutter. The xTool S1 sets a new standard for laser cutt...

View full details Sold out

Sold out

Elevate Your Creativity to New Heights with the xTool M1 Laser Engraver. Unleash your artistic vision with the xTool M1 - the ultimate Smart Laser ...

View full details Sale

Sale

FLUX Beamo 30W Laser Cutter & Engraver: The World's Smallest Desktop CO2 Laser Engraver and Cutter. Bring your creative ideas to life with the...

View full details Sold out

Sold out

Meet the xTool F1 Ultra 20W Fiber & Diode Dual Laser Engraver, the world's first and best 20W dual laser system. This groundbreaking machine co...

View full details Sold out

Sold out

Unleash the power of precision with the xTool F1 - the world's first portable laser engraver that seamlessly combines a 2W infrared laser and a 10W...

View full details Sale

Sale

Elevate your creative pursuits with the Ortur Laser Master 3 - a 20W powerhouse diode laser engraver that delivers unparalleled speed and precision...

View full details Save $150.00

Save $150.00

Unlock your creativity and conquer the world of precision laser engraving and cutting with the revolutionary Ortur Laser Master 2 Pro. The Ortur La...

View full details Save $800.00

Save $800.00

Meet the Laser Pecker 4 - the world's first dual laser engraver that redefines the possibilities. The LaserPecker 4 redefines the possibilities of ...

View full details Save $400.00

Save $400.00

Meet the Laser Pecker 2 - the ultimate tool for DIY enthusiasts, crafters, and small-scale professionals. Unlock your creativity and elevate your D...

View full details Sale

Sale

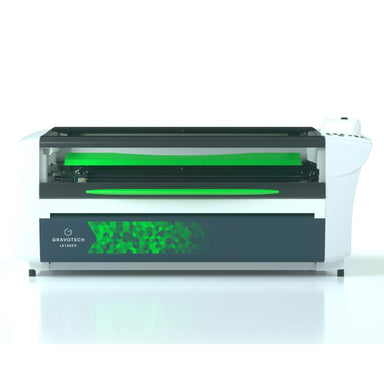

Elevate Your Engraving Capabilities with the Gravotech LS100EX Laser Engraving Machine With its large marking area, choice of CO2 or Fiber laser s...

View full details Sale

Sale

Revolutionize Your Engraving with the Gravotech LS100 Laser Engraving Machine Ever wanted to instantly engrave personalized items for your custome...

View full details Sale

Sale

Unleash industrial precision with the FSL PS48 Pro-Series Laser - the ultimate solution for heavy-duty engraving needs Experience industrial-grade ...

View full details Sale

Sale

Unleash industrial precision with the FSL PS36 Pro-Series Laser - the ultimate solution for heavy-duty engraving needs Experience industrial-grade ...

View full details Save $-8,995.00

Save $-8,995.00

Unleash industrial precision with the FSL PS24 Pro-Series Laser - the ultimate solution for heavy-duty engraving needs Experience industrial-grade ...

View full details Sale

Sale

Unleash industrial precision with the FSL PS20 Pro-Series Laser - the ultimate solution for heavy-duty engraving needs Experience industrial-grade ...

View full details Sale

Sale

Unleash your creativity with the power of the FSL Muse Titan Desktop CO2 Laser Cutter and Engraver - the largest desktop laser on the market! An in...

View full details Sale

Sale

Unlock your creative power with the precision and versatility of the FSL Muse Core CO2 Laser Cutter and Engraver Looking for the perfect machine to...

View full details Sale

Sale

Bring your visions to life like never before with the FSL Muse 3D Autofocus CO2 Laser Cutter and Engraver Are you ready to bring your laser engravi...

View full details Sold out

Sold out

Experience the future of desktop fabrication with the FLUX BeamBox Pro 50W CO2 Laser Cutter & Engraver. Introducing the FLUX BeamBox Pro 50W C...

View full details Save $40.00

Save $40.00

Supercharge Your Workflow with the FLUX HEXA 60W CO2 Laser Cutter. Introducing the FLUX Hexa 60W CO2 Laser Cutter & Engraver – a cutting-edge ...

View full detailsCO2 lasers are the most effective for cutting wood due to their high power and precision. A wood laser cutting machine with a CO2 laser can cut through various types of wood, including plywood, MDF, and hardwood, providing clean and smooth edges.

While a wood laser engraver and cutter offers precision, it can produce burn marks on edges, especially on thicker materials. Some types of wood, like resin-rich or oily woods, may also release strong fumes when cut. Proper ventilation and testing different settings can help minimize these issues.

The cutting depth depends on the power of the woodworking laser engraver. A standard 40W CO2 laser can cut up to 1/4 inch, while a more powerful 100W machine can handle up to 1 inch of wood. Multiple passes may be needed for thicker materials.

Shipping Insurance ($89)