Thinking of diving into laser engraving? Short answer: it’s awesome—but not without risks. From toxic fumes to fire hazards, Laser Engravers for Small Businesses demand caution. Stick around, because we’ll unpack the hidden downsides, safety must-knows, and how to avoid turning your workshop into a smoky disaster zone.

What Are the Disadvantages and Hazards of Laser Engraving?

Operational Risks to Be Aware Of When Laser Engraving

Fire Hazards, Fumes, and Ventilation

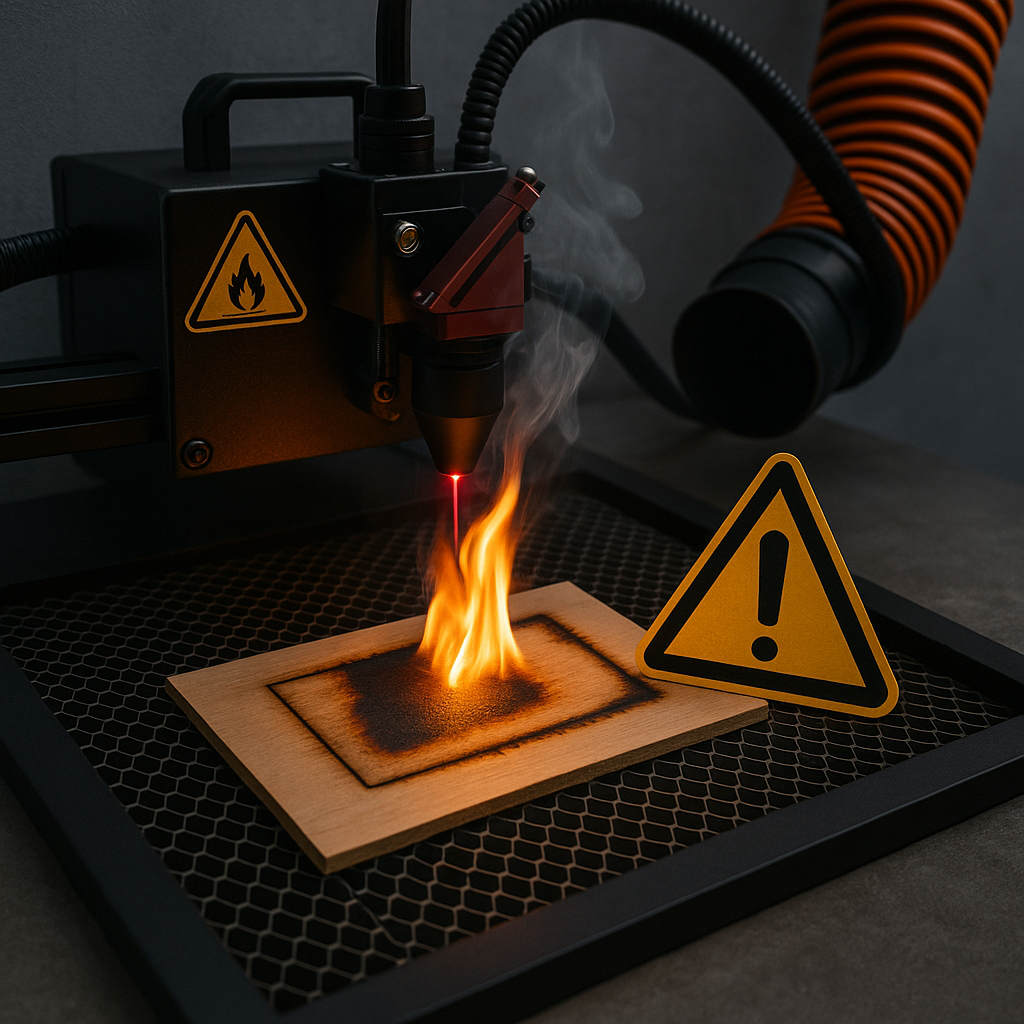

Think of a laser engraver as a tiny controlled fire machine. When that concentrated beam hits wood, leather, or acrylic, it’s essentially burning its way through. That means sparks, smoke, and sometimes little flare-ups. Plenty of beginners have learned the hard way when a job left running unattended turned into scorched material—or worse.

The fumes are another big deal. Acrylic smells like melted plastic, leather smells like a bonfire, and certain plastics (like PVC) release toxic chlorine gas when engraved. Breathing that in isn’t just unpleasant—it’s dangerous. This is why proper ventilation, fans, or dedicated fume extractors aren’t optional accessories; they’re essential health investments.

Real-life example: a home-based crafter engraving acrylic keychains discovered she was getting daily headaches. Once she added a fume extractor, the headaches disappeared. The difference was literally night and day.

Eye Safety and Proper Shielding

Lasers may not look intimidating, but they can cause irreversible eye damage in seconds. Even a reflected beam bouncing off a polished surface can do harm. There are engravers who only realized this risk after accidentally damaging a lens with reflected light. That mistake could just as easily have been their eyes.

Safety glasses rated for your laser’s wavelength are your best friend here. Some operators even install tinted shields around their machines for extra protection. It’s one of those areas where a $30 pair of glasses can save your vision for life—arguably the best return on investment you’ll ever make.

Material and Process Limitations

Reflective Materials (Glass, Mirrors) Risks

Engraving mirrors and glass sounds amazing until you try it. The beam often bounces unpredictably, damaging the machine or creating patchy results. Even if it doesn’t cause direct harm, you’re likely to see inconsistent depth or uneven frosting.

Experienced engravers often work around this by engraving the backside of coated glass or using a special marking spray to reduce reflectivity. It’s possible to get beautiful results, but it’s a trickier learning curve than with standard materials like wood or acrylic.

Burn Marks and Microfractures on Materials

Materials don’t always cooperate. Wood can scorch along the edges, leaving blackened marks that need sanding or sealing. Fabrics like leather may curl or warp under the heat. And stone or glass can develop microfractures—tiny cracks that aren’t obvious at first but weaken the structure.

Imagine handing over an engraved glass award only for it to crack when the recipient picks it up. Not exactly a great brand moment. The way to reduce these risks is careful calibration: adjusting laser speed, power, and making test runs on scraps before touching the final piece.

Laser Machine Constraints

Fixed-Focus vs Auto-Focus Limitations

Focusing sounds simple until you’re the one hunched over a machine adjusting heights by millimeters. Fixed-focus systems require you to manually measure and set the laser for each job. It’s time-consuming and introduces human error—forget to adjust, and the whole design might come out blurry or shallow.

Auto-focus systems solve a lot of this, automatically adjusting based on material thickness. But they’re not perfect—transparent or warped materials can trick the sensor. One jeweler told me her auto-focus system would misfire on curved rings, forcing her back to manual settings anyway. So even with fancy tech, there’s still a learning curve.

Maintenance Costs and Failure Points

Laser engravers don’t just run forever without attention. CO₂ tubes wear out, usually every 1–3 years, and replacements can cost several hundred dollars. Mirrors, lenses, and belts all need regular cleaning and eventual replacement. Skip maintenance, and your crisp engravings quickly turn into fuzzy disappointments.

Fiber lasers last longer, often tens of thousands of hours, but when something does fail, it’s not a $200 fix—it can run into the thousands. Regular upkeep is the difference between steady business and a machine that dies in the middle of a big client order. Treat maintenance like a non-negotiable business cost, not an afterthought.

Market Saturation and Competition

Price Pressure from Mass Producers (Etsy, OEMs)

Laser engraving is hot right now—which means everyone wants a piece of the pie. Etsy is full of sellers pumping out personalized items, and overseas manufacturers flood the market with dirt-cheap alternatives. Customers see a cutting board for $20 and wonder why yours costs $50.

Competing on price alone is a losing battle. A solo engraver can’t undercut mass producers with bulk materials and factory-scale efficiency. This is one of the hardest lessons new business owners learn when they step into the market.

Protecting a Niche and Maintaining Profitability

The businesses that thrive don’t try to be the cheapest—they carve out a niche. Maybe it’s heirloom-quality woodwork, luxury corporate gifts, or ultra-fast turnaround for local businesses. By leaning into areas where mass producers can’t compete, you make price less important and value more obvious.

One local engraver I know built her business around wedding décor. Instead of generic items, she offered fully personalized packages—signs, glassware, favors—delivered within weeks. Brides aren’t shopping for the cheapest option; they’re shopping for trust, service, and memorable products. That focus let her charge premium prices and grow while others fought in the bargain bin.

Leave a comment