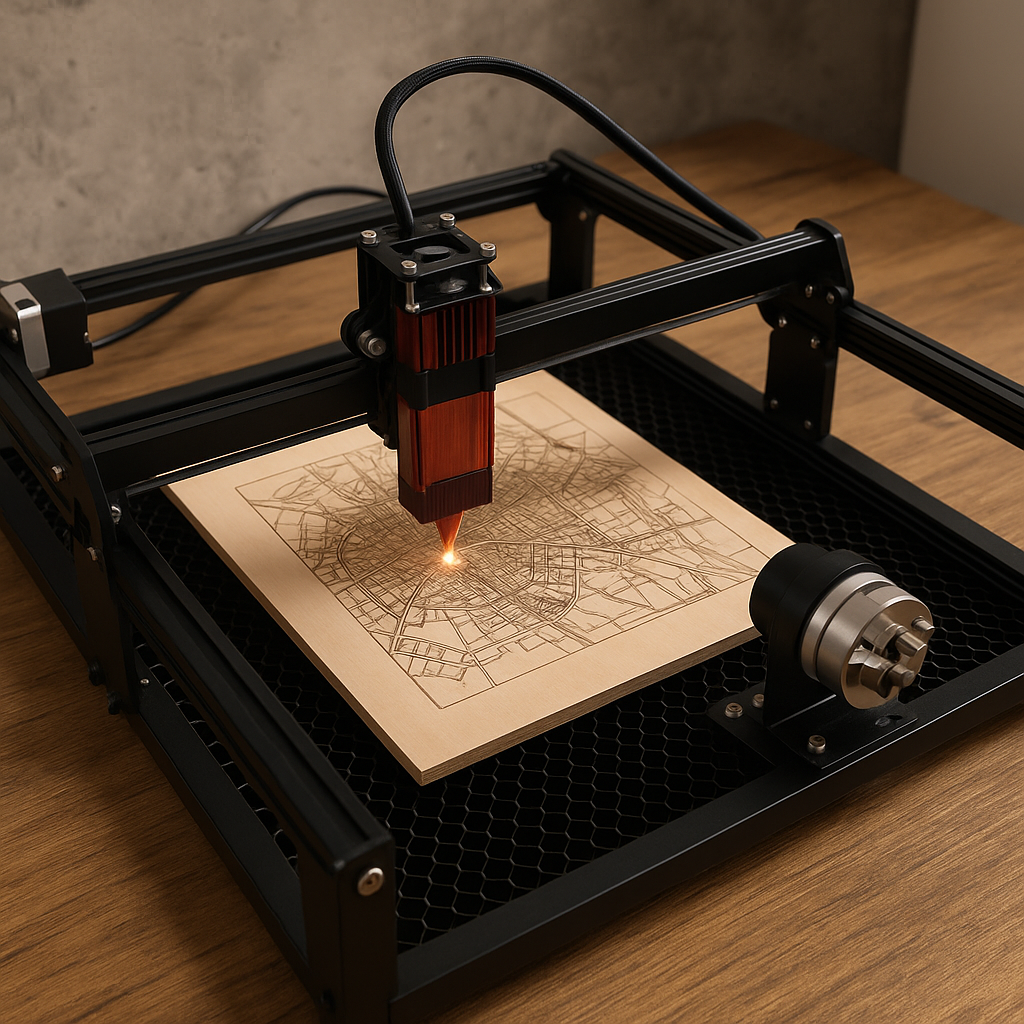

Thinking about laser engravers for small businesses? Short answer: pick the machine that matches your materials, budget, and goals. But before you grab the first shiny gadget, read on—you’ll learn how CO₂, Fiber, and Diode options stack up and which one fuels your business growth.

How to Choose the Right Laser Engraver for Your Small Business

Machine Features That Matter

Work Area, Laser Type, Automation (Auto-Focus, Conveyor, Rotary)

Think of the work area as your canvas. A small 8x8-inch bed is fine for coasters and keychains, but what if a customer asks for a 24-inch wedding sign? Suddenly, you’re turning down jobs. That’s why it pays to future-proof—go bigger if your budget and space allow.

The laser type sets the rules of the game.

-

CO₂ lasers are the “all-rounders” for wood, acrylic, glass, leather, and fabric.

-

Fiber lasers are the specialists—if you need to etch barcodes into stainless steel or personalize aluminum bottles, they’re unbeatable.

-

Diode lasers are the scrappy middle ground. Affordable, compact, and versatile, but they take longer on tougher materials.

Automation features can turn a one-person operation into a streamlined mini-factory. Imagine engraving 200 mugs: without a rotary attachment, you’re stuck doing one at a time. Or think about custom signs—auto-focus saves endless trial-and-error adjusting for material thickness. Add a conveyor system, and suddenly you’re running small production batches instead of babysitting every piece.

Build Quality and Safety Features

A shaky frame is like trying to draw a straight line on a bumpy bus—it just doesn’t work. Look for machines with solid construction, smooth rails, and reinforced housings that can handle the vibrations of long engraving sessions.

And safety? It’s non-negotiable. CO₂ lasers, for example, produce fumes when cutting wood or acrylic. Without proper enclosures and ventilation, your “side hustle” could quickly turn into a health hazard. Emergency stop buttons, fire-resistant housings, and laser-shielding lids are worth every extra dollar. A safe, sturdy machine isn’t just about compliance—it’s about keeping your shop running without surprises.

Material Compatibility & Flexibility

Metals (Aluminum, Stainless), Polymers, Wood, Acrylic

Here’s where business owners often trip up: buying a machine that won’t engrave the materials they actually sell. For example, a leather goods shop won’t need a fiber laser—but a jewelry shop will.

-

Metals: Fiber lasers can mark stainless steel medical tools, create QR codes on aluminum parts, or engrave custom pendants. CO₂ and diode lasers struggle here, unless you’re working with coated or anodized metals.

-

Polymers: Both CO₂ and diode lasers shine on plastics. Imagine engraving logos into phone cases or custom badges—affordable materials, high profit margin.

-

Wood: The go-to for CO₂ lasers. Rustic signs, branded cutting boards, even intricate puzzles are possible. The warm finish and texture make wood products hugely popular.

-

Acrylic: If you’ve ever seen glowing LED signs, chances are they were cut with a CO₂ laser. Crisp, clean edges and light diffusion make acrylic a bestseller for gift shops.

Emerging Materials Like Glass and Stone

Glass and stone aren’t everyday engraving jobs, but they can set you apart. A winery, for instance, could offer custom-etched wine glasses. A funeral home might request engraved stone plaques. These niche products command higher prices and attract clients who want something unique.

CO₂ lasers can achieve frosted designs on glassware—perfect for branding pint glasses or wedding favors. For stone, settings need to be dialed in carefully, but the payoff is impressive. A simple granite tile can be transformed into a permanent photo or memorial. Mastering these materials adds another layer of flexibility to your business.

Brand Comparison & Reliability

xTool, ComMarker, Glowforge, WeCreat Pros/Cons

The brand you choose isn’t just about the machine—it’s about the ecosystem that comes with it.

-

xTool: Known for affordability and modularity. You can start small with a diode laser, then add CO₂ options later. Community support is strong, so troubleshooting is easier. Downsides? Power limitations compared to premium machines.

-

ComMarker: Fiber laser experts. If metals are your bread and butter, ComMarker offers speed, precision, and durability. The flip side is price—they’re an investment, not an entry-level tool.

-

Glowforge: Marketed as the “iPhone of laser engravers.” Sleek design, user-friendly interface, and a quick learning curve. It’s perfect for makers who want minimal setup. But there’s a catch: their cloud-based software locks you into subscriptions, and you can’t always work offline.

-

WeCreat: Newer on the scene with simple, user-friendly machines. They’re great for beginners who want plug-and-play. But since the brand is young, long-term support and part availability aren’t as established.

Support Ecosystems and Software (LightBurn, MakeIt!)

Good hardware without solid software is like a sports car without a steering wheel. LightBurn is widely loved because it works with multiple brands, is affordable, and lets you design, import, and control jobs from one interface. For businesses, this flexibility is gold.

On the other hand, brand-locked ecosystems like MakeIt! (used by Glowforge) are polished and beginner-friendly. They’re fantastic if you just want to drag, drop, and engrave. But if you want advanced settings, offline access, or custom workflows, these ecosystems can feel restrictive. For businesses planning to scale, open software often makes more sense.

Evaluating Long-Term Value of your Laser Engraver

Lifespan and Parts Availability

A laser engraver isn’t a disposable gadget—it’s equipment. CO₂ lasers have tubes that need replacing every couple of years, depending on use. Fiber lasers typically last longer, sometimes 50,000+ hours, but their upfront cost is higher. Diodes are affordable but often need diode swaps with heavy use.

The key question: can you get parts easily? Established brands like xTool or ComMarker usually have spare parts in stock. Lesser-known brands might leave you scrambling on forums for a replacement lens. Downtime costs money, so parts availability should be a top priority when making your choice.

Electricity Usage and Maintenance Needs

Running costs sneak up quickly if you don’t plan for them. CO₂ lasers are more power-hungry and need regular cleaning of mirrors and lenses. Fiber lasers are efficient, with fewer moving parts to maintain. Diode lasers use less electricity but may not be as durable for high-volume production.

Maintenance isn’t glamorous, but it’s essential. Picture this: a busy holiday season, orders piling up, and your laser quits because of a dirty lens you didn’t clean. Regular upkeep—wiping optics, checking ventilation, lubricating rails—turns a machine into a long-term profit maker instead of a short-lived frustration.

Leave a comment