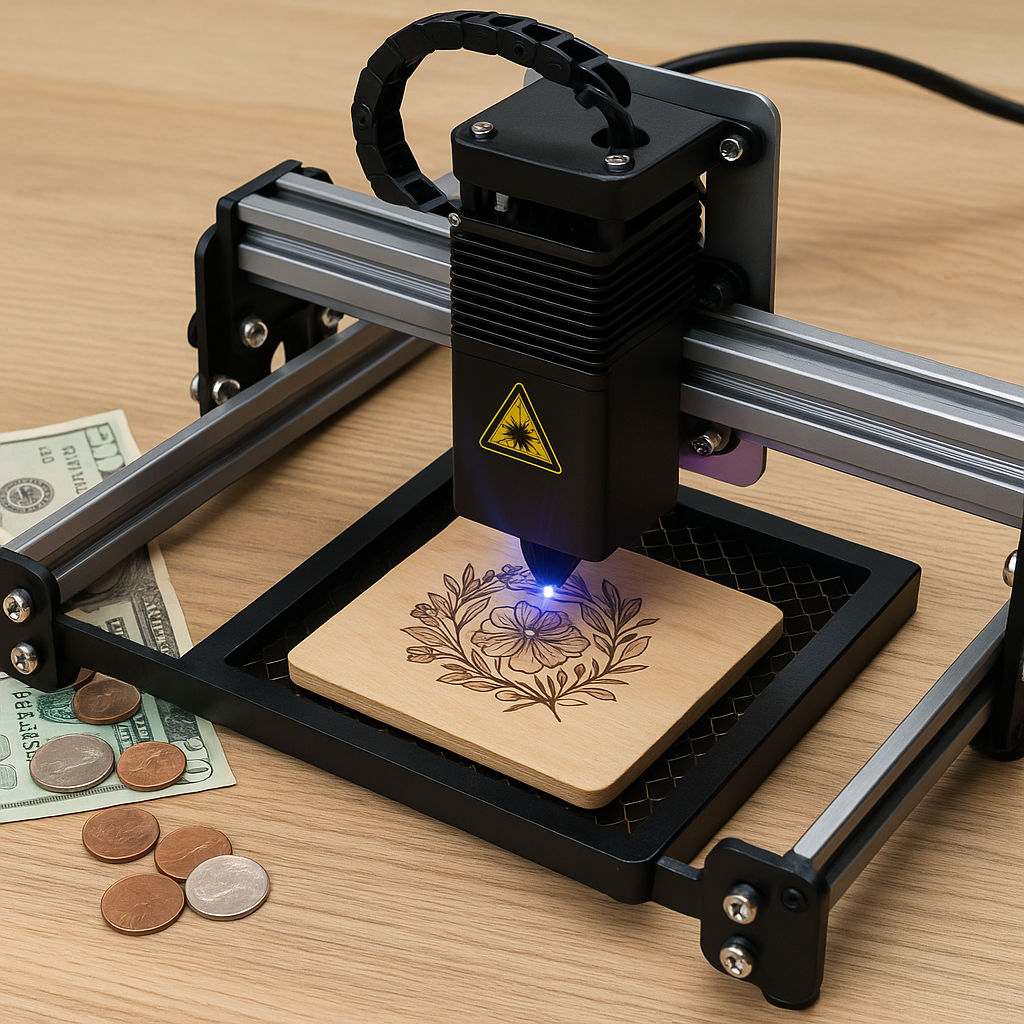

Wondering if it’s worth buying a laser engraver right now? Short answer: yes—demand is booming, and Laser Engravers for Small Businesses are more powerful and affordable than ever. But before you hit “buy now,” stick around—we’ll cover costs, types, and trends to help you choose wisely.

Is It Worth Buying a Laser Engraving Machine Right Now?

Return on Investment for Small Businesses

Breakeven Timeline with Typical Orders

Every purchase for a small business boils down to one thing: when does it start making money back? With laser engravers, the breakeven point can be surprisingly quick.

Take a $2,000 CO₂ machine. Sell 80 custom cutting boards at $25 profit margin each, and you’re already in the green. Add seasonal products like Christmas ornaments or wedding signage, and many owners recoup their investment within three to six months.

Think about it this way: a single bulk order from a corporate client—say, 200 engraved pens or mugs—could cover half the machine’s cost in one go. For creative entrepreneurs, the challenge isn’t finding customers, it’s keeping up with demand once word spreads.

Scaling Beyond Hobbyist to Consistent Revenue

It usually starts small. Maybe you’re engraving tumblers for friends or selling a few signs at craft fairs. But once people see your work, the requests start rolling in: “Can you do our company awards?” or “Can you make custom gifts for my wedding?”

This is where a hobby turns into a business. Platforms like Etsy, Shopify, and even local Facebook groups are filled with buyers looking for unique, personalized products. Scaling isn’t about reinventing the wheel—it’s about creating repeatable systems. Engravers let you batch orders, standardize your designs, and deliver consistent quality.

And here’s the kicker: customization carries a premium. People will pay more for something that feels unique. That’s why engravers for small businesses aren’t just tools—they’re profit machines.

Things to Consider Before Buying

Workspace Setup and Ventilation Concerns

One mistake new owners make is underestimating the space they need. A diode engraver might fit on your desk, but a mid-sized CO₂ machine can easily take up a dining table. And that’s before you factor in the exhaust system, cooling equipment, or storage for materials.

Ventilation is non-negotiable. Cutting acrylic or leather smells terrible without a proper exhaust, and fumes from certain plastics can even be dangerous. Many business owners set up their engravers in garages, workshops, or spare rooms with windows for venting. Some invest in filtration systems so they can operate safely indoors.

If you’re running this from home, ask yourself: do you have the space, airflow, and noise tolerance? Planning this upfront avoids major headaches later.

Safety Certifications and Training Needs

Lasers are powerful—powerful enough to burn, cut, and, if mishandled, cause real harm. That’s why safety features aren’t optional. Look for machines with certifications (like CE or FDA), enclosed housings, and emergency stop buttons. A good engraver should make you feel confident, not nervous.

Training doesn’t have to mean formal classes, though those exist. Many machine makers offer online tutorials, and communities on YouTube or Reddit are full of tips from experienced users. Spending time learning proper settings, cleaning routines, and safe operating habits isn’t just smart—it’s money-saving. Fewer mistakes mean less wasted material and happier customers.

Pros and Cons of Owning vs Outsourcing

Control Over Quality vs Equipment Cost

Here’s the honest trade-off: owning gives you control, outsourcing keeps your wallet heavier. With your own machine, you decide on the finish, tweak settings for perfection, and test new designs whenever inspiration strikes. That flexibility is worth gold when you’re building a brand based on quality.

On the other hand, machines aren’t free. A professional-grade fiber engraver can run $5,000–$10,000. If your volume is low or occasional, outsourcing might actually save you money. But if you’re filling orders weekly, outsourcing costs can add up faster than buying your own equipment.

Speed of Delivery vs Capital Outlay

Speed is where owning really shines. Imagine a customer emails late Friday, begging for 15 engraved awards by Monday. With your own engraver, you can make it happen. Outsourcing? Not a chance. That speed builds reputation, and reputation builds repeat business.

But of course, the speed comes at the cost of that initial outlay. You’re tying up capital in a machine rather than keeping it in the bank. For businesses that value agility and turnaround time, it’s a worthwhile trade. For those testing the waters, outsourcing can be a smart starting point until the volume justifies ownership.

DIY vs Professional Use Cases

Starting Small vs Specialized Customization

If you’re brand new, don’t overcomplicate it. A $500–$700 diode engraver can handle wood coasters, leather wallets, or acrylic ornaments. You’ll learn the basics, start making sales, and figure out which products actually resonate with buyers.

But once you see where the demand lies, upgrading can unlock bigger opportunities. Jewelers need fiber lasers for engraving rings and watches with hairline precision. Sign makers benefit from large-format CO₂ machines that can slice through acrylic sheets. These aren’t side hustle tools—they’re professional equipment designed for consistent, high-value output.

One approach is to start with DIY gear and reinvest profits into bigger machines. Another is to skip straight to pro-level if you already know your niche. Either way, the engraver you choose should match your goals, not the other way around.

Leave a comment