Sale

Sale

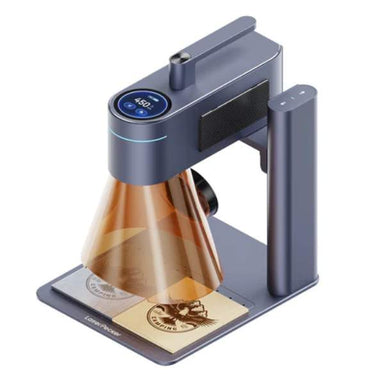

Make your mark with the LaserPecker LP5 - the most capable, lightest, and most compact engraver in its class. Unlock a world of creative possibilit...

View full detailsHave you ever wanted to make your own custom designs on wood, leather, or glass but thought it was too expensive? A cheap laser engraver can help you start creating amazing projects without spending a lot of money. Whether you’re making gifts, decorations, or just trying something new, a beginner laser engraver makes it easy and fun to get started.

Our budget laser engraver collection is perfect for anyone who wants to try laser engraving for the first time or build a small business from home. These affordable laser engravers are simple to set up, safe to use, and work on many materials—so you can bring your creative ideas to life without breaking the bank.

Sale

Sale

Make your mark with the LaserPecker LP5 - the most capable, lightest, and most compact engraver in its class. Unlock a world of creative possibilit...

View full details Sold out

Sold out

Elevate Your Creations with the FLUX Beambox 40W CO2 Laser Cutter. The FLUX Beambox 40W CO2 Laser Cutter & Engraver is a compact yet powerful ...

View full details Save $305.00

Save $305.00

FLUX Beamo 30W Laser Cutter & Engraver: The World's Smallest Desktop CO2 Laser Engraver and Cutter. Bring your creative ideas to life with the...

View full details Save $300.00

Save $300.00

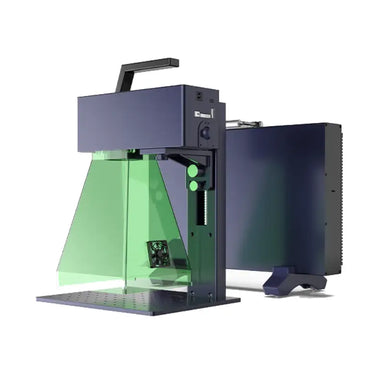

Elevate your Metal & Plastic engraving game with the LaserPecker 3 Portable Infrared Laser Engraver. Unleash your creativity with the unparalle...

View full details Sale

Sale

Elevate your creative pursuits with the Ortur Laser Master 3 - a 20W powerhouse diode laser engraver that delivers unparalleled speed and precision...

View full details Sold out

Sold out

Elevate Your Creativity to New Heights with the xTool M1 Laser Engraver. Unleash your artistic vision with the xTool M1 - the ultimate Smart Laser ...

View full details Sold out

Sold out

Unleash Your Creative Genius with the Unparalleled Power of the xTool S1 Laser Engraver and Cutter. The xTool S1 sets a new standard for laser cutt...

View full details Sold out

Sold out

Unleash the power of precision with the xTool F1 - the world's first portable laser engraver that seamlessly combines a 2W infrared laser and a 10W...

View full details Save $600.00

Save $600.00

Meet the Laser Pecker 4 - the world's first dual laser engraver that redefines the possibilities. The LaserPecker 4 redefines the possibilities of ...

View full details Save $400.00

Save $400.00

Meet the Laser Pecker 2 - the ultimate tool for DIY enthusiasts, crafters, and small-scale professionals. Unlock your creativity and elevate your D...

View full details Save $150.00

Save $150.00

Unlock your creativity and conquer the world of precision laser engraving and cutting with the revolutionary Ortur Laser Master 2 Pro. The Ortur La...

View full details Sale

Sale

Unlock your creative power with the precision and versatility of the FSL Muse Core CO2 Laser Cutter and Engraver Looking for the perfect machine to...

View full details Sale

Sale

Unlock the Power of Precision Engraving on Metals and Plastics with the Gweike G2. Unlock a world of creative possibilities with the Gweike Cloud G...

View full details Sale

Sale

Unleash a powerhouse of laser precision in your workspace with the Gweike Cloud 50W CO2 Laser Cutter & Engraver. Introducing the Gweike Cloud 5...

View full details Save $0.00

Save $0.00

Unleash Your Creativity with the Powerful Creality Falcon2 Pro 60W Laser Engraver. Experience the power of next-generation laser technology with t...

View full details Save $0.00

Save $0.00

Unlock Your Creative Potential with the Creality Falcon2 Pro 40W Laser Engraver & Cutter. Introducing the Creality Falcon2 Pro, a state-of-the...

View full details Save $0.00

Save $0.00

Bring Your Designs to Life with the Creality Falcon2 Pro 22W Laser Engraver & Cutter. Unlock the full potential of your creativity with the Cr...

View full details Save $120.00

Save $120.00

Unlock a world of creativity with the Creality Falcon2 12W Laser Engraver & Cutter. Boundless Creativity Meets Precision Craftsmanship. This a...

View full details Save $480.00

Save $480.00

Craft Masterpieces Faster Than Ever with the Creality Falcon2 22W Laser Engraver. Bring your wildest ideas to life with the Creality Falcon2 22W ...

View full details Save $300.00

Save $300.00

Unlock the power of precision with the Creality Falcon2 40W Laser Engraver & Cutter - a game-changing tool that elevates your creative potentia...

View full details Save $960.00

Save $960.00

Unleash your creativity and precision with the NOX 50W CO2 Laser Cutter & Engraver. Transform your workspace into a high-tech digital fabricat...

View full details Save $160.00

Save $160.00

Unleash your creativity with the powerful Gweike G1 10W laser cutter & engraver! Elevate your projects to the next level with the Gweike G1 10W...

View full details Save $0.00

Save $0.00

Cut, engrave, and create with precision with the Glowforge Pro and make every project your masterpiece. Turn your imagination into real projects wi...

View full details Save $0.00

Save $0.00

Cut, engrave, and score with incredible precision with the Glowforge Plus. The Glowforge Plus 3D Laser Printer turns creative ideas into real, hand...

View full detailsIf you’re new to engraving, a beginner laser engraver with simple controls and safety features is a great choice. Look for a cheap laser engraver that works with wood, acrylic, and leather, so you can try different projects and see what you enjoy most.

Yes! A budget laser engraver can be a smart buy for beginners or hobbyists. These affordable laser engravers often handle light projects well and let you learn the basics before investing in a larger machine.

The best budget laser engravers offer an affordable way to start engraving wood, leather, and acrylic. A cheap laser engraver is perfect for personalizing gifts and exploring creative projects without a big investment.

A best entry-level laser engraver should be easy to set up, safe, and beginner-friendly. If you need more versatility, the best budget laser cutters can both engrave and cut, making them great for DIY projects.

Whether you need a cheap laser cutter or a reliable best affordable laser cutter, our collection has options to fit your budget and help you get started!

Shipping Insurance ($89)