Ultimate Guide to Acrylic Laser Cutters: Choosing, Using, and Maintaining

Introduction

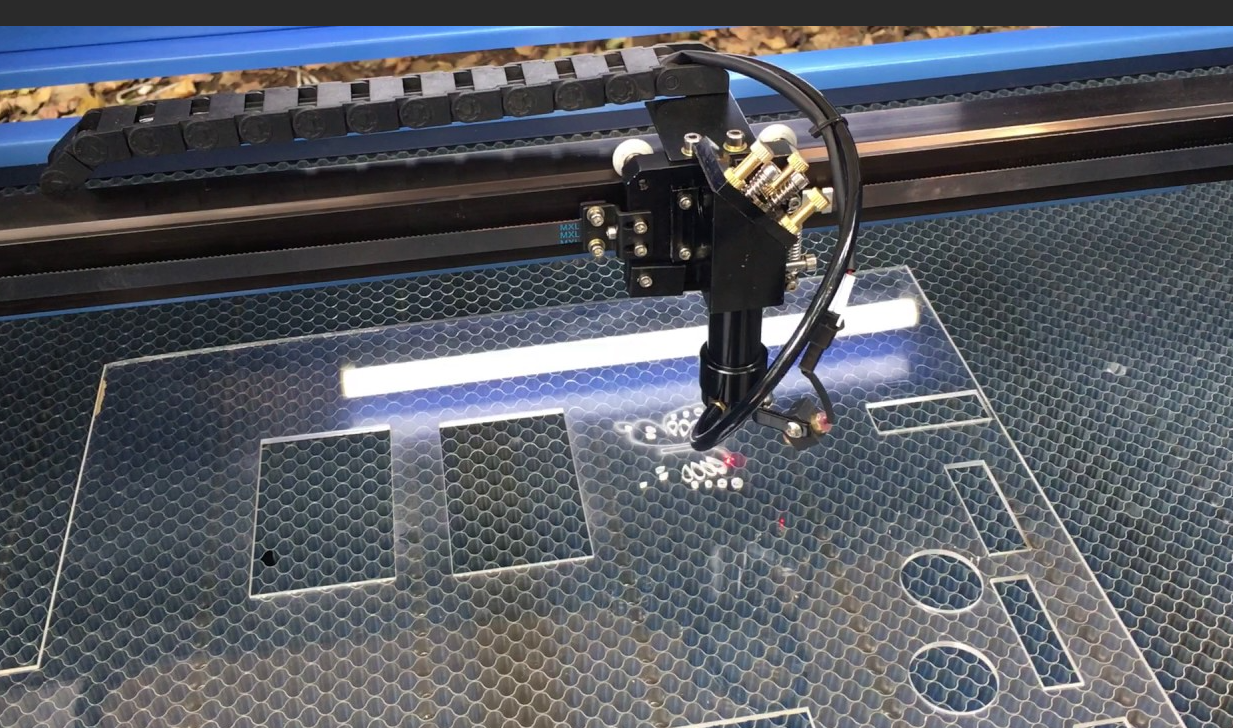

Acrylic laser cutters are indispensable tools in various industries, offering precision and versatility for cutting and engraving acrylic materials. This guide explores everything you need to know about choosing, using, and maintaining acrylic laser cutters to achieve optimal results in your projects.

Importance of Choosing the Right Acrylic Laser Cutter

Selecting the appropriate acrylic laser cutter can significantly impact the quality and efficiency of your work. Whether you're focusing on intricate designs or high-volume production, the right machine ensures you achieve your desired outcomes consistently.

Overview of Acrylic Laser Cutting Technology

Acrylic laser cutting utilizes advanced technology to deliver precise cuts and intricate engravings. By harnessing laser energy, these machines can achieve detailed designs with minimal material wastage, making them ideal for both prototyping and large-scale production.

Why Acrylic Laser Cutters Matter

Precision and Versatility in Design

Acrylic laser cutters excel in creating intricate designs with sharp edges and smooth finishes. They offer unmatched precision, allowing for the realization of complex shapes and patterns with ease.

Efficiency and Cost-effectiveness in Production

Efficiency is a hallmark of acrylic laser cutters, reducing production time and costs compared to traditional methods. Their ability to handle multiple tasks, from cutting to engraving, streamlines workflows and enhances overall productivity.

Understanding Acrylic Laser Cutting Technology

Laser Types: CO2, Fiber, and Diode

Acrylic laser cutters primarily use CO2 lasers for their ability to efficiently cut through acrylic materials. Fiber and diode lasers, while less common for acrylic cutting, offer unique advantages in specific applications such as marking and fine engraving.

How Each Type Works for Acrylic Cutting

CO2 lasers emit infrared light that is absorbed by acrylic, vaporizing it with precision. Fiber lasers use a different wavelength for marking and cutting, suitable for thinner acrylic sheets. Diode lasers are ideal for engraving detailed designs on acrylic surfaces.

Why Diode Lasers Are Unsuitable For Acrylic Cutting

Diode lasers are not suitable for acrylic cutting primarily due to their wavelength inefficiency and limited power output. Acrylic does not absorb the visible to near-infrared light emitted by diode lasers effectively, which is crucial for converting laser energy into the heat necessary for cutting. In contrast, CO2 lasers, operating at a wavelength of around 10,600 nm, are well-absorbed by acrylic, enabling efficient cutting. Additionally, diode lasers generally have lower power levels compared to CO2 lasers, which limits their ability to cut through thicker acrylic sheets.

Moreover, the beam quality of diode lasers is inferior to that of CO2 lasers, resulting in less focused and precise cuts. Diode lasers produce a larger, more divergent beam, leading to less clean edges and lower overall cutting quality. CO2 lasers, with their tightly focused beams, can achieve fine, intricate cuts with smooth edges, essential for high-quality acrylic work. While diode lasers are cheaper and more efficient for some applications, their performance in acrylic cutting is significantly lower, making CO2 lasers the preferred choice for their superior precision and efficiency.

Choosing the Best Acrylic Laser Cutter

When selecting an acrylic laser cutter, consider several crucial factors:

Factors to Consider When Buying

- Power and Speed Requirements: Match the machine's power output and cutting speed with your project needs.

- Cutting Area and Bed Size: Ensure the machine accommodates the size of acrylic sheets you work with.

- Software Compatibility and Ease of Use: Compatible software enhances workflow efficiency, while user-friendly interfaces simplify operation.

Top Acrylic Laser Cutter Brands and Models

Review and Comparison of Top Laser Engraving Machines

xTool P2 55W Desktop CO2 Laser Cutter

The xTool P2 is a 55W CO2 laser cutter designed for desktop use. It combines high power with a compact design, making it suitable for various woodworking projects. The P2 offers excellent cutting and engraving capabilities, and its user-friendly interface ensures smooth operation even for beginners.

Gweike Cloud Basic II 50W CO2 Laser Cutter and Engraver

The Gweike Cloud is a 50W CO2 laser cutter and engraver that offers a balance of power and affordability. It features a user-friendly design and robust construction, making it ideal for both hobbyists and small businesses. The machine’s performance and versatility make it a reliable choice for various woodworking tasks.

FSL Muse 3D Desktop CO2 Laser Engraver

The FSL Muse 3D is a desktop CO2 laser engraver that features advanced 3D engraving capabilities. Its high precision and versatility make it suitable for intricate designs and detailed work. The Muse 3D’s intuitive software and robust build quality have earned it positive reviews from both beginners and professionals.

Glowforge Pro

The Glowforge Pro is a high-end CO2 laser cutter and engraver known for its advanced features and exceptional performance. It offers a large bed size, high power, and compatibility with various materials, making it suitable for complex projects. The Glowforge Pro’s ease of use and reliable results have made it a favorite among professional woodworkers.

Practical Tips for Choosing the Right Machine

Assessing Your Needs: Hobbyist vs. Professional Use

Before purchasing a laser engraver, assess whether you need it for hobbyist or professional use. Hobbyists may prioritize affordability and ease of use, while professionals might focus on power, precision, and advanced features to handle high-volume and complex projects.

Budgeting Wisely: Getting the Best Value

Determine your budget and seek machines that offer the best value within that range. While entry-level models are affordable, investing in mid-range or high-end machines can provide better performance and durability, ultimately offering more value for your money.

Space and Setup Considerations: Planning Your Workspace

Consider the available space in your workspace and choose a laser engraver that fits comfortably. Ensure you have adequate ventilation and power supply for the machine. Proper setup and planning will help you create an efficient and safe working environment.

Maintenance and Safety: Ensuring Longevity and Safe Operation

Regular maintenance is crucial for the longevity of your laser engraver. Follow the manufacturer’s guidelines for cleaning and upkeep. Prioritize safety by wearing protective gear, ensuring proper ventilation, and following safe operating procedures to prevent accidents and injuries.

Leave a comment