Materials UV Laser Engravers Can Cut and Engrave

Ever feel like UV Laser Engravers are the Swiss Army knives of the maker world? Short answer: they can engrave metals, plastics, glass, wood, and even PCBs. But here’s the reality check: UV lasers are designed to engrave, not cut. Stick around to see why these precision powerhouses are every industry’s secret weapon for detail, durability, and versatility.

Understanding UV Lasers: The "Cold Marking" Advantage

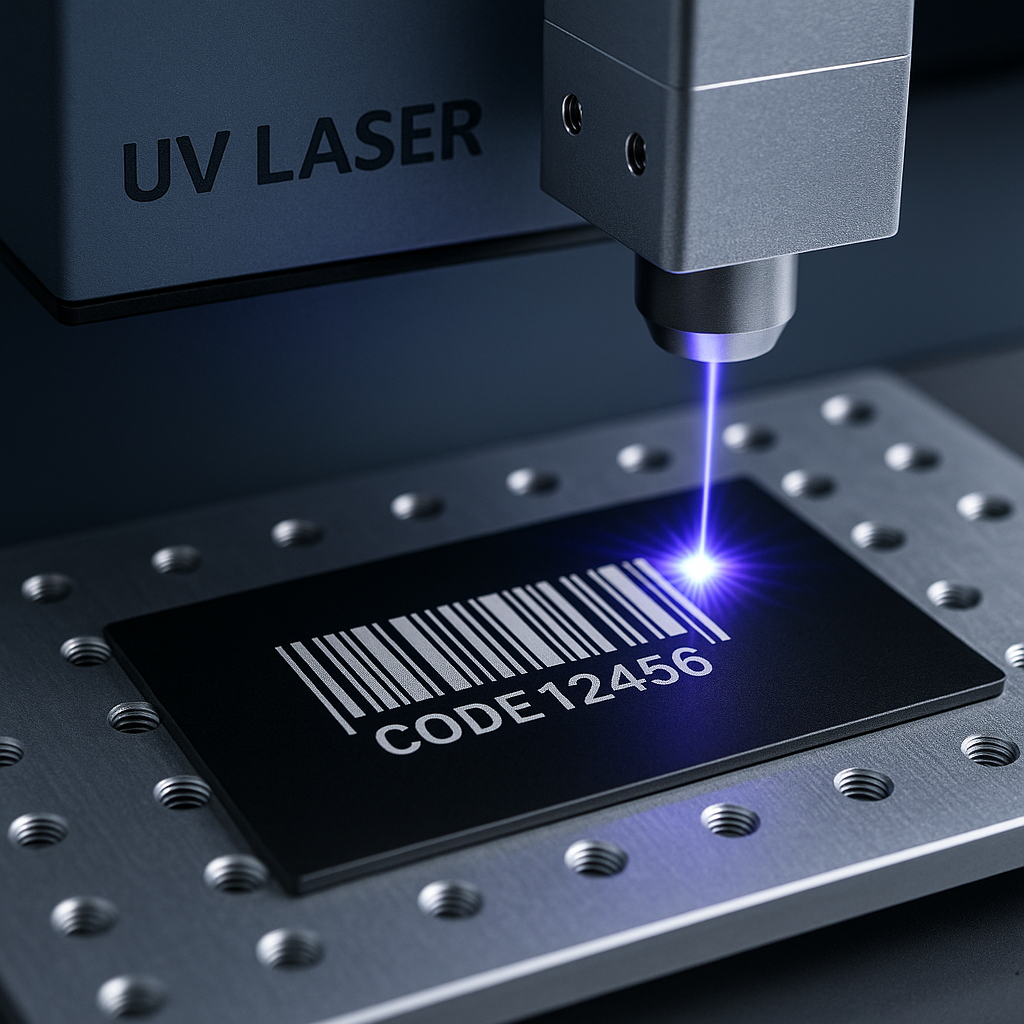

When people picture lasers, they often imagine beams hot enough to slice steel in half. UV lasers take a very different approach. Instead of blasting through with heat, they rely on what’s called cold marking — a process that creates marks without burning, cracking, or warping the material.

This makes UV lasers the specialists in the engraving world. They’re the go-to machines when detail, precision, and delicacy matter more than raw power.

The Technology Behind the Engraving

UV lasers work at a much shorter wavelength (around 355 nm) than fiber or CO₂ systems. Because of this, the light is absorbed quickly on the surface instead of penetrating deep and heating everything up.

The result is a permanent, high-contrast mark with no ugly scorch marks. It’s why you’ll find UV lasers marking tiny serial numbers on circuit boards or delicate branding on medical instruments.

Engraving vs. Cutting Capabilities

Here’s the reality check: UV lasers are designed to engrave, not cut. They’re the artist, not the lumberjack.

If you need a logo etched onto glass or a barcode engraved on plastic, they’ll do it flawlessly. But if you’re hoping to slice through thick metal or hardwood, you’ll want a CO₂ or fiber laser instead.

What Materials Can a UV Laser Engrave? (Comprehensive List)

Plastics and Polymers

The Ideal Choice for Heat-Sensitive Plastics

Plastics tend to melt or bubble under heat. That’s why UV lasers shine here. They engrave crisp designs while leaving the plastic surface smooth and intact.

Common Plastics Engraved by UV Lasers

-

ABS — common in electronics and casings.

-

Acrylic — widely used for signs and displays.

-

Polycarbonate — durable material in aerospace and automotive parts.

-

Specialized polymers — found in medical and industrial environments.

Ceramics and Stone

From decorative ceramic tiles to technical stone components, UV lasers handle both with ease. The markings are permanent, detailed, and resistant to wear. Perfect for anything from luxury home goods to aerospace-grade materials.

Paper, Cardboard, and Fabrics

Surprisingly, UV lasers can engrave even the most delicate substrates. Imagine custom invitations, branded packaging, or intricate patterns on fabrics. Because there’s no blade involved, the process is clean and contact-free.

Leather and Other Organic Materials

Whether it’s initials on a wallet, a logo on a leather bag, or branding for handmade goods, UV lasers engrave leather with sharp, stylish results. No burns, no singeing — just professional-looking designs.

Can a UV Laser Engrave Glass?

How UV Lasers Mark Glass without Cracking

Glass and heat don’t get along. But UV lasers sidestep that issue entirely. They deliver energy to the surface without heating the entire object, which prevents cracks or breakage.

The Frosted vs. Transparent Marking Effect

The finish depends on your settings. You can achieve a frosted, etched look that’s perfect for decorative glassware. Or you can create subtle, transparent markings often used in electronics and branding.

Can a UV Laser Cut Wood?

The Limitations of UV Laser Cutting on Wood

Wood is thick, fibrous, and unpredictable. UV lasers simply don’t have the power to cut it efficiently.

Engraving Wood: A Different Result

What they can do is engrave. UV lasers create high-contrast, detailed designs on wooden surfaces — great for signage, crafts, and personalization.

Comparing UV and CO₂ Laser Effects on Wood

If cutting through wood is the goal, a CO₂ laser is still king. But for fine, detailed surface engravings, UV lasers deliver results CO₂ machines can’t match.

Can UV Lasers Cut Metal?

The Difference Between Engraving and Cutting Metal

UV lasers can mark or engrave metals, but they won’t cut through them. That’s the job of a fiber laser.

Ideal Metals for UV Laser Engraving

-

Anodized aluminum

-

Stainless steel (surface marking)

-

Coated or plated metals

-

Precious metals like gold and silver

When to Use a Fiber Laser Instead

If you’re cutting sheets of steel or engraving deep into tough alloys, fiber lasers are the right choice. UV lasers specialize in surface-level detail and precision.

Materials a UV Laser Cannot Engrave or Cut

Why Some Materials Are Not Recommended

Certain materials just don’t work with UV lasers. Very dense woods, thick stones, or heavy industrial metals fall outside their comfort zone. Attempting to engrave them will either waste time or damage the surface.

Safety and Fumes to Be Aware Of

Some plastics — especially PVC — release toxic fumes when lasered. Always double-check material safety and make sure your workspace is well-ventilated before starting.

You May Also Like:

Leave a comment