Filtrabox Fume Extractor Maintenance: Maximize Efficiency & Lifespan

Think of Filtrabox Laser Fume Extractors like cars—they run best with regular tune-ups. Short answer: maintenance maximizes efficiency and lifespan. Keep reading to learn how simple checks, filter swaps, and cleaning routines save money, protect your health, and keep your extractor working like a champ for years.

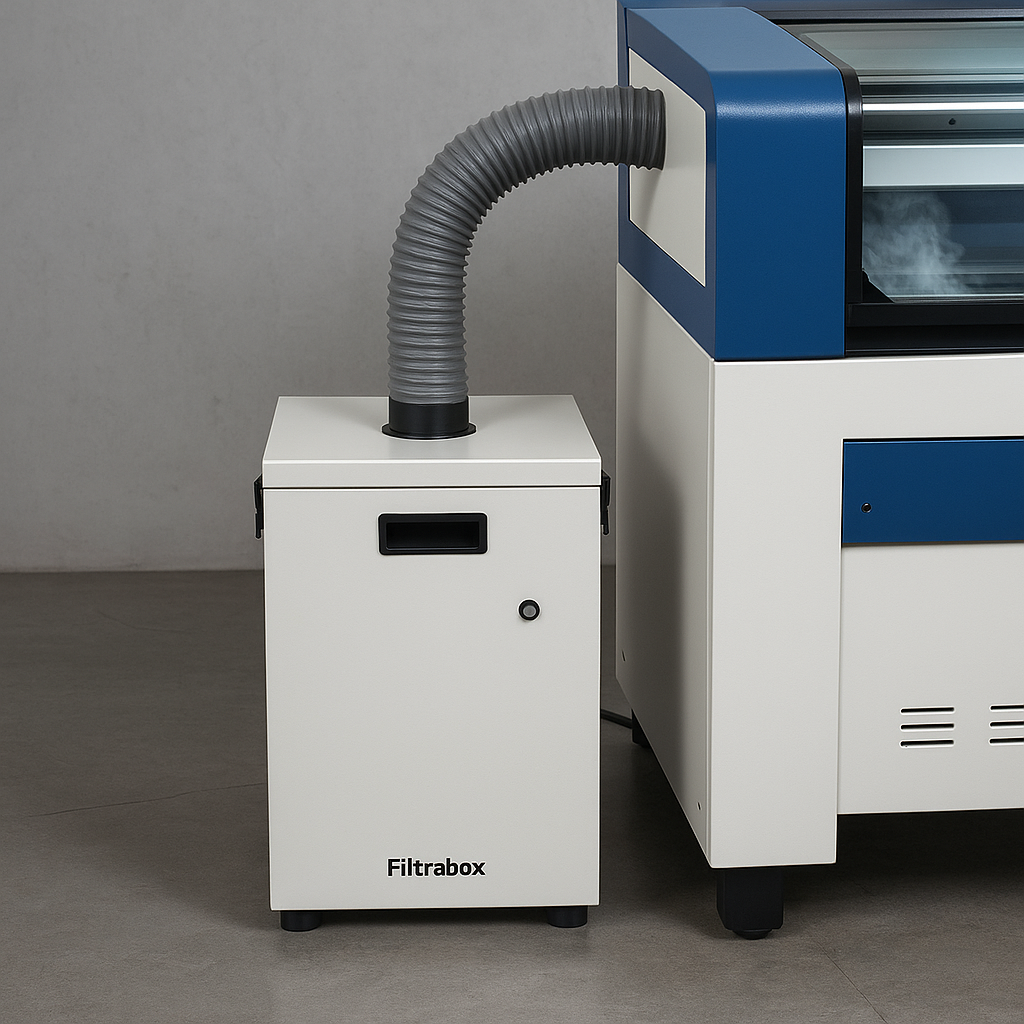

Maintaining Your Filtrabox for Long-Term Use

Your Filtrabox Laser Fume Extractor is built like a tank, but even the toughest gear needs regular care. Skip maintenance, and you’ll notice reduced suction, noisier operation, and filters wearing out faster than expected. Stay on top of upkeep, though, and your Filtrabox will run quietly in the background for years, protecting your lungs and your workspace.

Think of maintenance as the small price you pay for peace of mind. Just like you wouldn’t drive thousands of miles without checking the oil, you shouldn’t expect your extractor to work at full tilt without a little attention. A few minutes here and there can save you hundreds in repairs later.

Regular Cleaning & Visual Inspections

Your Filtrabox works hard to pull in smoke, dust, and fumes—but that also means it collects debris that needs clearing out. Letting buildup go unchecked is like letting a sink clog up: performance suffers, and eventually, things back up.

A quick inspection every couple of weeks is usually enough. Look for dust around the intake, check that hoses are secure, and glance at the filters. You don’t need to take the whole unit apart—just build a habit of giving it a once-over. If something looks off, fix it before it grows into a bigger problem.

Cartridge Pressure Checks

Cartridge filters act like the extractor’s lungs, but over time they can “get winded.” Pressure checks tell you how hard the filter is working. If pressure rises higher than normal, airflow is restricted and the motor is straining.

Running with clogged cartridges is like sprinting while breathing through a straw—it’s doable for a short while, but it won’t last long. A pressure check takes seconds but can extend the life of both the filter and the motor.

Dust Drawer & Flame Arrestor Cleaning

The dust drawer is easy to forget, but think of it like the lint trap in your dryer. If you don’t empty it, efficiency plummets, and things get messy. Make it part of your monthly routine to check and clear it.

The flame arrestor is another silent hero. It keeps sparks from traveling where they shouldn’t, but only if it’s clear of dust. A quick wipe with a dry cloth keeps it effective. Regular cleaning not only improves performance but also ensures your Filtrabox stays safe during heavy-duty jobs.

Replacement Parts & Filter Lifespan

Filters are consumables, plain and simple. They’re designed to trap particles and fumes, but once full, they lose their punch. Replacing them on schedule is cheaper and safer than trying to stretch their life.

Think of it like air filters in your car or HVAC system—you don’t wait until you can’t breathe through them to swap them out. Staying ahead of filter changes keeps your air clean, your extractor efficient, and your motor stress-free.

When to Use HEPA vs Carbon vs Pre-Filters

Each filter type has its specialty:

-

Pre-filters: Grab the big stuff—dust, fibers, and larger debris. They’re inexpensive and should be swapped the most often, usually every 1–3 months.

-

HEPA filters: Designed for the invisible. They capture fine particles like smoke and micro-dust down to 0.3 microns. These usually last 6–12 months, depending on use.

-

Carbon filters: Handle smells and fumes. If you’re cutting acrylic, plastics, or other materials with strong odors, these are essential. Replace every 6–12 months—or sooner if you catch whiffs of those nasty smells again.

Using the right filter mix ensures your extractor tackles every type of contaminant, from obvious dust clouds to invisible chemical vapors.

Ordering Replacement Filters and Costs

Running out of filters mid-job is frustrating—and avoidable. Order spares in advance and keep a small stockpile. Pre-filters are the most affordable, while HEPA and carbon units cost more but last longer.

Budgeting for filter replacements is smart, especially in busy workshops. Treat them like printer ink or cutting blades—part of your consumables. Having extras on hand means you’ll never have to choose between stopping production and running with a clogged filter.

Troubleshooting Common Filtrabox Issues

Even with great maintenance, small hiccups can happen. The good news is most problems have simple fixes you can handle yourself. Knowing what to look for keeps downtime minimal and saves you from unnecessary repair costs.

Reduced Airflow

If suction drops, start with the basics. A clogged pre-filter is often the culprit—swap it out and test again. If airflow still feels weak, check the hose for kinks, cracks, or blockages.

Sometimes the issue is as simple as a loose connection letting air escape. Tighten fittings and reseal ducts. Nine times out of ten, reduced airflow comes down to filters or hoses, not a major failure.

Unusual Noise and Filter Clogs

Weird noises are your Filtrabox’s way of saying, “Hey, something’s wrong.” Rattles and vibrations often mean loose screws, an imbalanced fan, or a dust clog.

Start by tightening fasteners and inspecting the fan. If you find dust clumps, clear them out. A clogged filter can also make the system groan—swapping it out often restores both quiet operation and strong performance. If noises persist, it might be time to get a professional to check for worn bearings or deeper mechanical issues.

You May Also Like:

Leave a comment