Sale

Sale

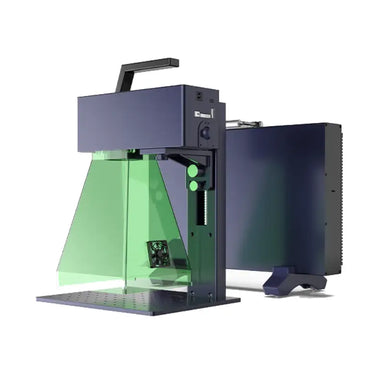

Unleash Your Creativity with the Compact, Cutting-Edge ComMarker B6 Fiber Laser Engraver. The ComMarker B6 Fiber Laser Engraver redefines portabil...

View full detailsLooking for a way to add detailed designs or markings to metal? A laser etching machine for metal makes it easy to create permanent engravings on stainless steel, aluminum, and more. Whether you need a laser cutter for metal to cut intricate shapes or a metal etching laser for detailed artwork, these machines offer precision and durability for every project.

From industrial applications to DIY projects, a laser engraving machine for metal ensures clean and accurate results. Whether you're personalizing jewelry, marking tools, or working with a metal laser cutting machine for home, laser technology provides a fast and efficient way to achieve professional-quality engravings. Start crafting with confidence!

Sale

Sale

Unleash Your Creativity with the Compact, Cutting-Edge ComMarker B6 Fiber Laser Engraver. The ComMarker B6 Fiber Laser Engraver redefines portabil...

View full details Save $1,000.00

Save $1,000.00

Bring portable engraving power to the next level with the Gweike G2 Max 50W fiber laser engraver that redefines precision and power. Discover next-...

View full details Sale

Sale

Introducing the ComMarker B6: The Precision Powerhouse for your Metal Engraving Needs. Unlock a new era of smart metal color engraving with the Co...

View full details Sale

Sale

Introducing the ComMarker Titan 1 JPT MOPA Fiber Laser Engraver - the ultimate solution for professionals who demand the best. The ComMarker Titan ...

View full details Sale

Sale

Unlock the Future of Precision Marking with the Gweike G6 Split Fiber Laser. Introducing the Gweike G6 Split Fiber Laser, the ultimate solution for...

View full details Sale

Sale

Unlock the Future of Precision Marking with the Gweike G6 MOPA Fiber Laser. Introducing the Gweike G6 MOPA Fiber Laser, the ultimate solution for h...

View full details Sale

Sale

The ComMarker B4 Fiber Laser is a groundbreaking marking machine designed to redefine engraving with unmatched precision, speed, and versatility. ...

View full details Sale

Sale

Make your mark with the LaserPecker LP5 - the most capable, lightest, and most compact engraver in its class. Unlock a world of creative possibilit...

View full details Sale

Sale

Unlock the Power of Precision Engraving on Metals and Plastics with the Gweike G2. Unlock a world of creative possibilities with the Gweike Cloud G...

View full details Save $800.00

Save $800.00

Meet the Laser Pecker 4 - the world's first dual laser engraver that redefines the possibilities. The LaserPecker 4 redefines the possibilities of ...

View full details Save $500.00

Save $500.00

Elevate your engraving game with the Gweike G2 Pro 30W, the cutting-edge fiber laser engraver that redefines precision and power. Experience the fu...

View full details Sold out

Sold out

Unleash the power of precision with the xTool F1 - the world's first portable laser engraver that seamlessly combines a 2W infrared laser and a 10W...

View full details Sold out

Sold out

Meet the xTool F1 Ultra 20W Fiber & Diode Dual Laser Engraver, the world's first and best 20W dual laser system. This groundbreaking machine co...

View full details Save $400.00

Save $400.00

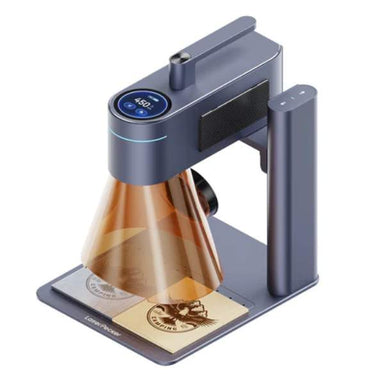

Elevate your Metal & Plastic engraving game with the LaserPecker 3 Portable Infrared Laser Engraver. Unleash your creativity with the unparalle...

View full details Sale

Sale

Meet the most versatile laser engraver on the market - the Gweike G7 UV Laser Engraver. 100x faster, 10x finer detail and 30x smaller spot sizes th...

View full details Sale

Sale

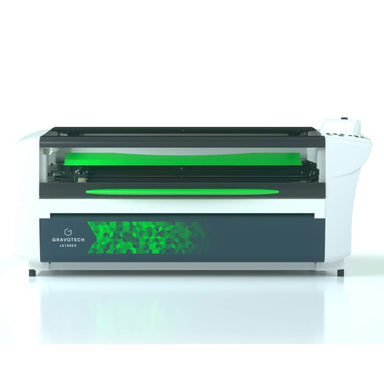

Elevate Your Engraving Capabilities with the Gravotech LS100EX Laser Engraving Machine With its large marking area, choice of CO2 or Fiber laser s...

View full details Sale

Sale

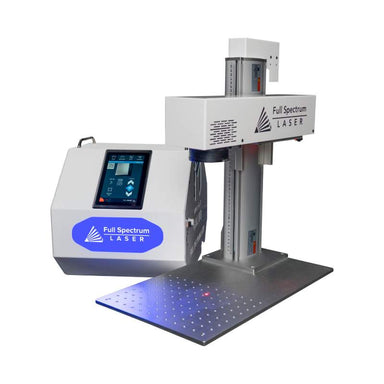

Get the power and precision you need with the FSL Muse Economy Fiber Open Galvo Laser Tired of slow, inaccurate results from your desktop laser? Th...

View full details Sale

Sale

Experience unparalleled power and precision with the FSL Muse MOPA Fiber Galvo Laser Tired of slow, inaccurate results from your desktop laser? The...

View full details Sale

Sale

Deploy the speed and precision of an UV laser source with the FSL Muse UV Galvo Laser 100x faster, 10x finer detail and 30x smaller spot sizes tha...

View full details Save $600.00

Save $600.00

Unlock the Power of Portable Precision with the EM-Smart One 20W Fiber Laser Engraver. Introducing the EM-Smart One 20W Fiber Laser Engraver - a g...

View full details Sale

Sale

Unlock Endless Possibilities with the EM-Smart Basic 20/25W Fiber Laser Engraver. The EM-Smart Basic 20/25W Fiber Laser Engraver is a cutting-edge...

View full details Save $400.00

Save $400.00

Portable Power, Precision, and Possibilities with the EM-Smart Nova 25W Fiber Laser Engraver. Elevate your engraving game with the EM-Smart Nova -...

View full details Sale

Sale

Monport GQ Fiber Laser Engraver & Marking Machine: Precision Meets Power. The Monport GQ Fiber Laser Engraver & Marking Machine delivers u...

View full details Sale

Sale

Experience the pinnacle of fiber laser marking with the Monport GA Integrated MOPA Fiber Laser Engraver & Marking Machine. Introducing the Monp...

View full detailsWhile a laser marking machine for metal offers precision, laser cutting can generate heat, leading to potential warping on thinner materials. The initial cost of a laser etching machine for metal can also be high, though it pays off in long-term efficiency and precision. Proper ventilation is necessary to manage fumes and metal dust produced during the cutting process.

Fiber lasers are the most effective for cutting metal due to their high power and efficiency. A metal laser cutting machine for home with a fiber laser can cut through stainless steel, aluminum, and brass with smooth, clean edges. CO2 lasers can also cut metal, but they require higher wattage and additional gas assistance.

Shipping Insurance ($89)